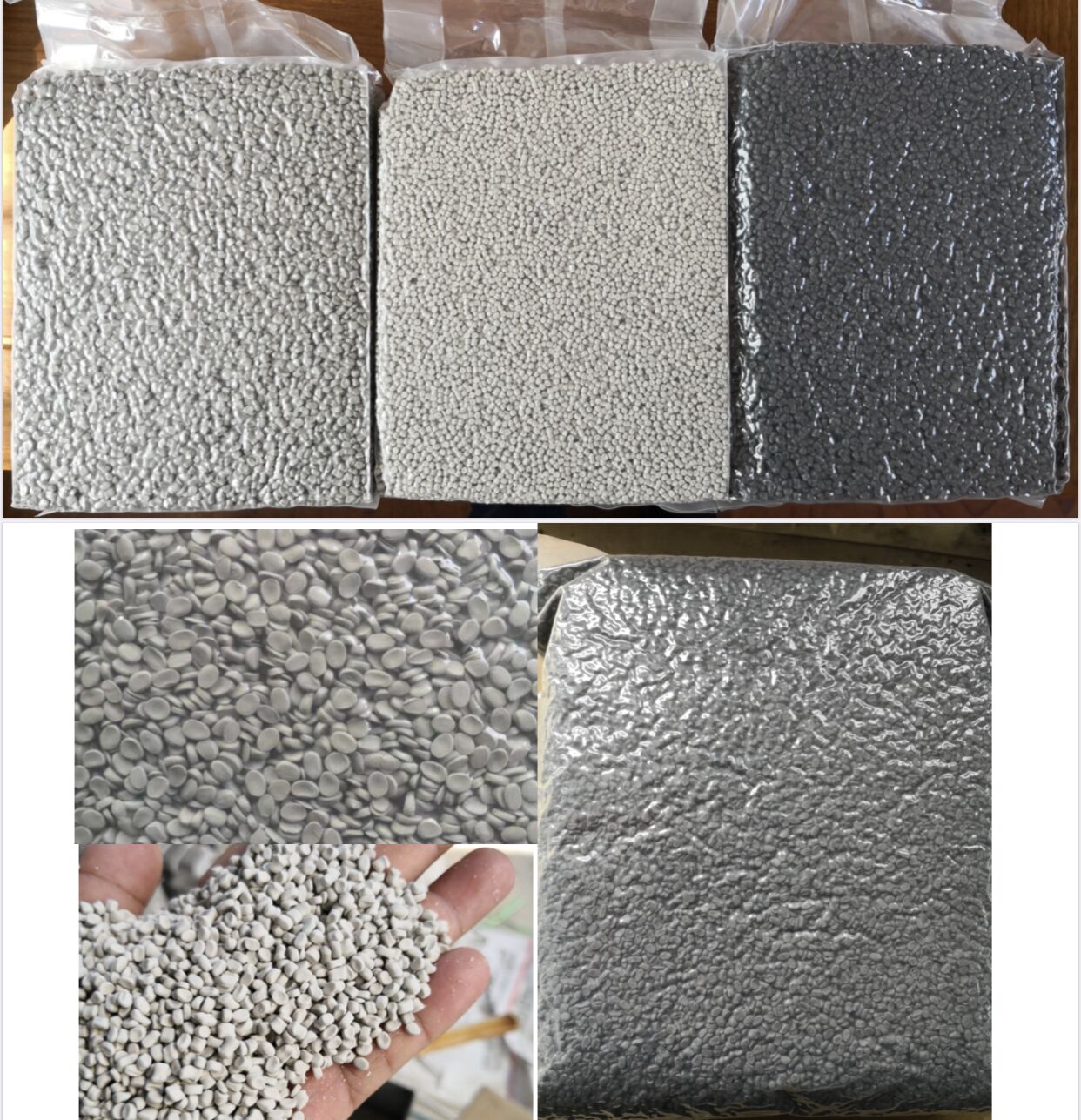

Plastic desiccant masterbatch : high-efficiency defoaming masterbatch (also called defoaming masterbatch,dehumidifying masterbatch, water-absorbing masterbatch,)

The high-efficiency desiccant masterbatch is suitable for all kinds of enterprises that use PE and PP recycled plastics for product production. The trace moisture contained in raw materials has a very serious impact on the production of plastic products. Therefore, companies generally use additional drying equipment to dry the plastic, which is a great waste of energy and manpower and increases the cost of the product. With this masterbatch, you only need to add it to the raw materials without any adjustments to the production process of the product. All problems such as bubbles, moiré, cracks, and spots caused by moisture can be eliminated, and there is no adverse effect on the physical and mechanical properties of the product. Impact, save time and electricity, improve production efficiency, and reduce costs. The masterbatch is non-toxic, non-odor, non-corrosive, and harmless to the human body.

How to use desiccant masterbatch :

Mix the desiccant masterbatch with the damp plastic raw material evenly, then the product can be processed and produced. If used in blow molding production, the addition ratio is 1.0% ~ 2.0%; if used in sheet and injection molding production, the addition ratio is 2% ~ 5%; the specific addition ratio should be determined by the user according to the moisture content of the plastic .

Application scope desiccant masterbatch:

Widely used in film products, bag products, sheet products and injection molded products. 5. Technical indicators: The test item indicators have an appearance of off-white particles, with good plasticization. Density: (g/cm3) 1.5±0.1 melt flow rate (g /10min) 15.0~25.0 Volatile matter (%) 1.5±0.5

Desiccant masterbatch Precautions:

1. Avoid moisture absorption before using this desiccant masterbatch;

2. When using, it is better to use the ingredients immediately;

3. Do not heat and dry together with damp plastic to avoid poor quality during processing;

4. Check whether the package is intact before opening the package, and heat seal the unused desiccant masterbatch as soon as possible.

Storage conditions:

Store in a clean, ventilated, dry, cool and clean place. Damaged masterbatch packaging and open storage are not allowed to avoid sun exposure and rain.