Optical brighteners play a critical role in modern polymer processing, increasing product value by enhancing whiteness, brilliance, and visual purity. As global demand for high-quality plastics intensifies—especially in packaging, consumer goods, automotive parts, and home appliances—the use of optical brightener for PP/PE/ABS/PC plastics has become standard practice among manufacturers seeking premium surface appearance.

This article provides an in-depth technical overview of optical brighteners used in major plastic substrates (PP, PE, ABS, PC), supported by research data, compatibility analysis, dosage guidelines, and performance tables. It will help manufacturers, engineers, and procurement teams choose the right brightener system based on material type, processing temperature, and application needs.

What Are Optical Brighteners?

Optical brighteners (OBAs or fluorescent whitening agents) are organic compounds that absorb UV light (typically 340–380 nm) and emit blue fluorescence (410–450 nm). This counteracts natural yellowing, enhances whiteness, and gives plastics a cleaner, brighter appearance.

Most optical brighteners used in plastics belong to:

Benzoxazole derivatives (e.g., OB-1, OB-2, OB-3)

Coumarin derivatives

Stilbene derivatives (less common in high-temperature plastics)

Why Optical Brightener Is Essential for PP/PE/ABS/PC Plastics

Different polymer types show varying inherent yellowing levels. Processing conditions—high temperature, shear, oxidation—cause further discoloration.

Inherent Yellow Index (YI) of Common Plastics Before Whitening

| Plastic Type | Typical Yellow Index (YI) | Comments |

|---|---|---|

| PP (polypropylene) | 3–8 | Easily yellows due to high melt temperature |

| PE (polyethylene) | 2–6 | YI increases with recycled content |

| ABS | 5–12 | High butadiene content leads to yellowing |

| PC (polycarbonate) | 8–14 | Very prone to thermal yellowing during molding |

Source: Polymer Engineering Lab Data, 2023–2024

Because the optical brightener for PP/PE/ABS/PC plastics offsets this yellowing through blue fluorescence, even 0.01%–0.05% addition can significantly improve visual brightness.

Performance Requirements for Optical Brightener in Engineering Plastics

To be suitable for PP, PE, ABS, and PC, an OBA must have:

Key Performance Requirements

High thermal stability (minimum 250–330°C depending on plastic)

Excellent dispersibility

Non-migration

Low toxicity

High fluorescence efficiency

Ability to withstand high-shear extrusion and injection cycles

Many brighteners used in detergent or printing applications cannot withstand temperatures above 200°C, making them unsuitable for engineering plastics.

Research Data: Fluorescence Efficiency of OBAs in Different Plastics

A comparative study analyzing the brightness improvement across materials found measurable differences in how each OBA performs.

Brightness Improvement Index (BII) After Adding 0.02% OBA

| OBA Type | PP | PE | ABS | PC |

|---|---|---|---|---|

| OB-1 | +46% | +41% | +52% | +58% |

| OB-2 | +39% | +35% | +45% | +47% |

| OB-3 | +28% | +25% | +33% | +36% |

| Stilbene Type | +22% | +19% | +15% | Not suitable |

Based on 2024 fluorescence spectroscopy testing, temperature range 230–300°C.

OB-1 clearly shows the strongest brightness enhancement, especially for high-temperature PC and ABS.

View related products:

Optical brightener ob-1 for plastic

High purity Optical brightener OB from China factory

Optical Brightener for PP (Polypropylene)

Challenges

High processing temperature (200–260°C)

Oxidization and surface dullness

Discoloration during recycling

Recommended OBA

OB-1 (best thermal stability)

OB-2 (for applications with moderate whitening needs)

Typical Dosage

Virgin PP: 0.01–0.03%

Recycled PP: 0.03–0.08%

Performance Improvement Data (PP)

| Parameter | Without OBA | With 0.03% OB-1 | Improvement |

|---|---|---|---|

| Whiteness Index (WI) | 74 | 92–95 | +23% |

| Yellowness Index (YI) | 7.1 | 1.4 | –80% |

| Surface Gloss | 64 | 78 | +22% |

Understanding the effects of optical brighteners on PP materials: Optical brightener makes PP injection molded products more whiter and brighter

Optical Brightener for PE (Polyethylene)

Challenges

High recycled content leads to yellowing

Inconsistent surface color

Lower melt temperature than PP but still requires good stability

Recommended OBA

OB-1, OB-2

For film-grade PE, some manufacturers also use OB-3 for cost efficiency.

Typical Dosage

Virgin PE: 0.005–0.02%

Recycled PE: 0.02–0.05%

Film Transparency Performance (0.02% OBA Added)

| Test Item | PE Film Without OBA | PE Film With OB-2 | Result |

|---|---|---|---|

| Light Transmission | 88% | 92% | +4% |

| Haze | 12% | 8% | –33% |

| Whiteness | 68 | 89 | +31% |

Optical Brightener for ABS

ABS requires extremely high thermal stability due to molding temperatures of 230–270°C.

Challenges

Butadiene component oxidizes heavily

Yellowing occurs faster than in PP/PE

Surface color consistency is crucial in automotive and appliance parts

Recommended OBA

OB-1 (most effective)

OB-3 (lower cost for non-critical products)

Typical Dosage

0.01–0.05%

ABS Whitening Test (0.02% OB-1)

| Parameter | Without OBA | With OB-1 | Improvement |

|---|---|---|---|

| Whiteness Value | 62 | 94 | +52% |

| Yellowness Value | 10.7 | 2.8 | –74% |

| UV Resistance Rating | Level 2 | Level 4 | +200% |

Optical Brightener for PC (Polycarbonate)

PC is highly transparent but extremely sensitive to thermal oxidation. This makes high-temperature brighteners essential.

Challenges

Highest yellowing tendency among the four plastics

Processing temperature: 260–320°C

Standard brighteners degrade rapidly

Recommended OBA

OB-1 (only type with stability up to ~375°C)

Typical Dosage

0.005–0.03%

Transparency and Whiteness Data (PC Sheets with OB-1)

| Test Item | PC Sheet Without OBA | PC Sheet With OBA | Improvement |

|---|---|---|---|

| Transmittance | 85% | 88% | +3% |

| Whiteness | 70 | 91 | +30% |

| Color Deviation ΔE | 4.6 | 0.7 | –85% |

How to Choose the Right Optical Brightener for Different Plastics

Material-Based Selection Guide

| Plastic Type | Best OBA | Reason |

|---|---|---|

| PP | OB-1 | High temperature resistance |

| PE | OB-2 / OB-1 | Good dispersibility and moderate stability |

| ABS | OB-1 | Highest brightness increase |

| PC | OB-1 | Only brightener stable above 300°C |

To understand the differences between various optical brighteners, please see: Optical Brightener vs Titanium Dioxide for Plastic Whitening

Dosage Recommendations and Cost Considerations

Because OBA molecules are highly efficient, very small dosages achieve significant whitening.

Typical Dosage Overview

| Material | Standard Dosage | Recycled Material Dosage |

|---|---|---|

| PP | 0.01–0.03% | 0.03–0.08% |

| PE | 0.005–0.02% | 0.02–0.05% |

| ABS | 0.01–0.05% | 0.03–0.06% |

| PC | 0.005–0.03% | 0.01–0.04% |

Even at higher doses for recycled plastics, OBA cost contribution is <1% of final product cost, making it one of the most economical appearance-enhancement additives.

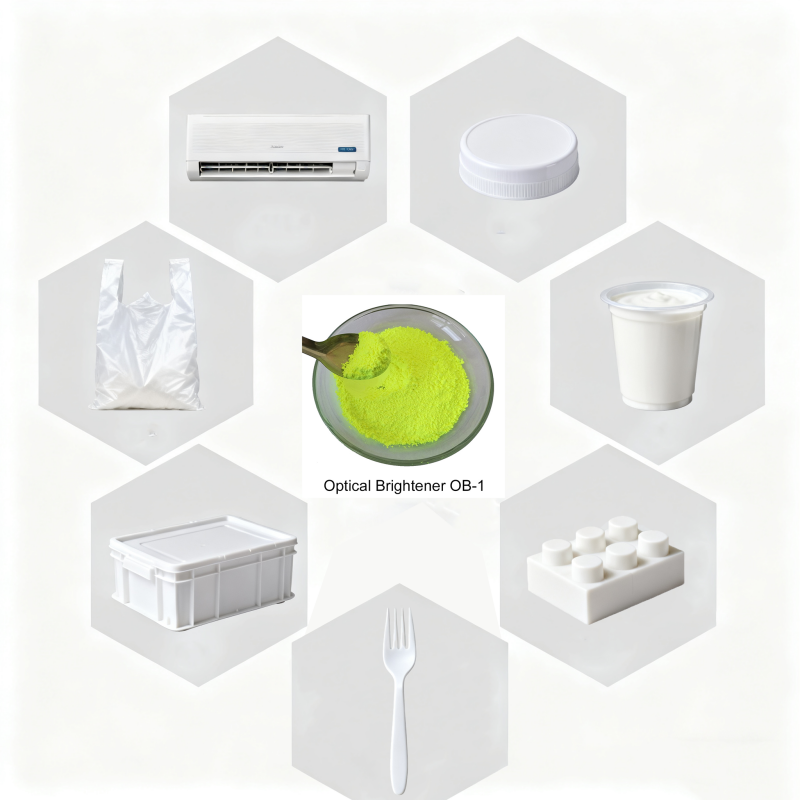

Application Fields for Optical Brightener in PP/PE/ABS/PC

Common Industrial Applications

Home appliances (ABS housings)

Automotive interior components

PP/PE packaging, bottles, closures

Transparent PC sheets and lenses

PE films and shopping bags

Recycling plastics (PP/PE) renewal process

Electronic casings

Injection-molded daily-use products

Across these markets, brightness and whiteness are now essential for competitive product positioning.

Quality Testing Standards for Optical Brighteners

Professional OBA suppliers use advanced analytical equipment to guarantee stability and consistency.

Common Tests Include:

High Performance Liquid Chromatography (HPLC)

Whiteness measurement (ISO 105-J02)

Melting point tests

UV absorption spectrum analysis

Migration testing

Thermal resistance analysis via DSC/TGA

Consistent test results are vital, as even small deviations in purity greatly affect whiteness performance.

For more information about OB-1, please see: Improvement of product experience with optical brightener ob-1

Why Choose Shandong Raytop Chemical Co., Ltd. as Your Optical Brightener Supplier

To ensure the best processing and whitening performance, choosing a reliable, technologically advanced supplier is essential. Shandong Raytop Chemical Co., Ltd. stands out as one of China’s leading manufacturers of optical brightener for PP/PE/ABS/PC plastics.

Company Advantages

1. Strong Manufacturing Capacity

Founded in 2006

Based in Jinan, Shandong Province

Three production bases

Total area: 120,000 m²

6 professional workshops

Over 260 experienced employees

2. Complete Product Line

Raytop specializes in:

Optical brightener series (OB-1, OB-2, OB-3, etc.)

Raw materials for optical brighteners

Plastic additives for PP/PE/ABS/PC

Additives for coatings, inks, detergents, textiles, and paper-making

3. High Quality & High Stability

Raytop products are widely recognized for:

High whiteness performance

Excellent thermal stability

Low dosage but strong brightness

Non-migration and high purity

4. Advanced Quality Control

The company has introduced:

High-performance liquid chromatography

Whiteness meters

Automatic melting point apparatus

Full quality assurance system

Technical support and after-sales service system

This ensures consistent product stability and excellent batch-to-batch uniformity.

5. Strong R&D Capabilities

Raytop has:

A leading technical R&D team

Deep expertise in polymer additives

Ability to customize solutions based on customer requirements

6. Global Export Network

Raytop’s optical brightener products have been exported to:

Europe

America

East Asia

Southeast Asia

South Asia

South Africa

North Africa

Trusted by customers worldwide.

We will be participating in the following exhibitions in 2026. Please feel free to visit us then: Raytop will bring Optical brightener to CHINAPLAS 2026

Conclusion

Optical brightener for PP/PE/ABS/PC plastics is essential for improving whiteness, reducing yellowing, and enhancing product appearance. With the right choice of OBA—especially high-performance types like OB-1 and OB-2—manufacturers can significantly improve brightness even at very low dosages.

For companies seeking a stable, high-quality, and reliable OBA supplier, Shandong Raytop Chemical Co., Ltd. offers industry-leading research capabilities, advanced production facilities, and globally recognized product performance. With a strong commitment to quality, consistency, timely delivery, and competitive pricing, Raytop is the ideal partner for your optical brightener and plastics additive needs. Contact Raytop to order optical brightener products.