Besides,Optical Brightener used in plastics,detergent optical brighteners,optical brightener aslo can be used in paper.some times people use optical brighteners powder or liquid to make the paper more white and high grade.Because

Optical Brightener is kind of additives can absorb UV light then emit visible blue light to reduce the yellowish and make the products more white.

Product Name | Optical Brightening Agent BBU |

CAS No. | 16470-24-9 |

C.I. No. | 220 |

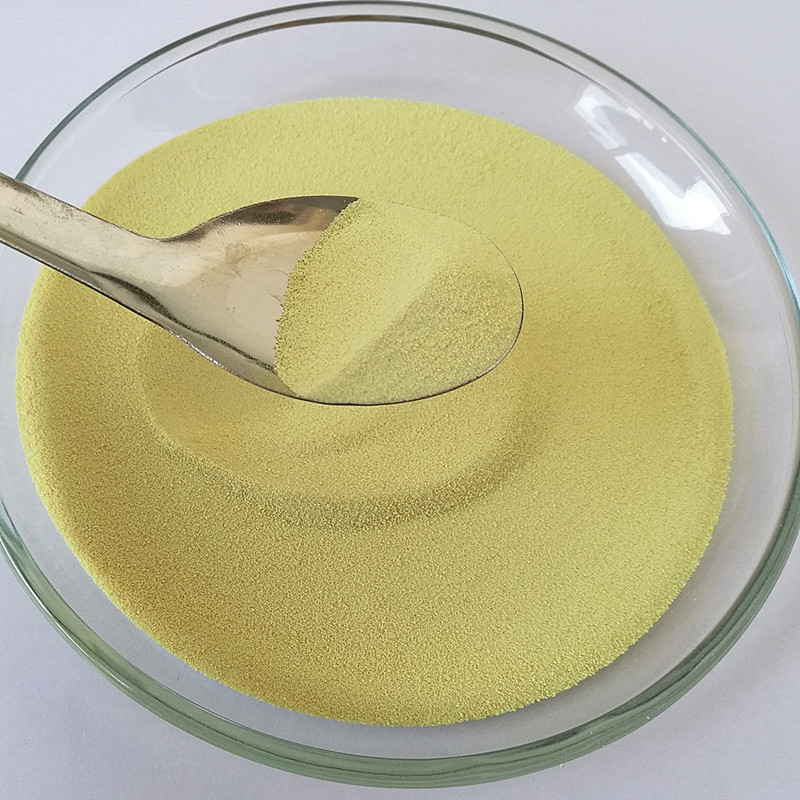

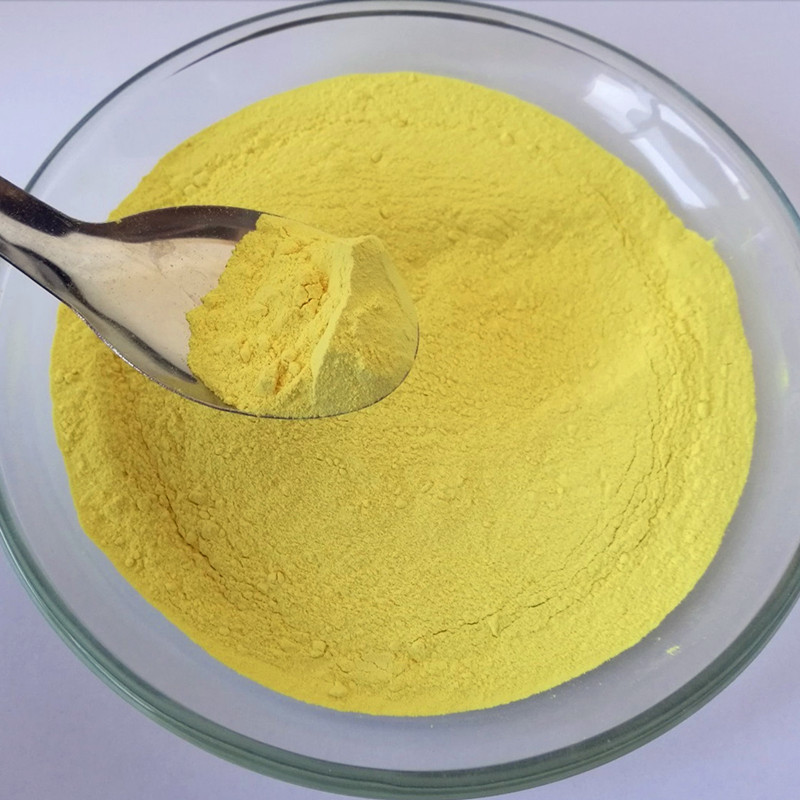

Technical Index | Appearance:straw yellow uniform powder Brightness:similar to-quite low Intensity:100(conmpare with standard) Water content,% ≤:5 Insoluble matter in water,% ≤:0.5 Fineness(180um residue),% ≤:10 |

Properties and use: | Cationic distyrene fluorescent brightener, with medium solubility in water and purplish blue fluoresoence,Use in pulp brightening, surface sizing and coating, etc, Can also be used to brighten cotton,T/C blends,fiax, polyamide fibers,and light-color textiles. |

Application method: | Paper making: Textile printing and dyeing: |