Since January this year, the titanium dioxide sector has continued to rise, and the price of titanium dioxide has also risen sharply. According to relevant data, since last year, the price of titanium concentrate has increased by about 50% . In 2021, the global economy began to recover. The rapid growth of the industry, the exhaustion of titanium ore stock resources and the limited new capacity have led to less elasticity of supply. The superimposed industry chain has entered an active replenishment cycle. It is expected that the supply and demand gap of titanium ore will continue to be maintained, which will push the price of titanium ore to continue to rise, and it is expected to reach new highs. In recent years, the titanium ore resources in the global mines have begun to be severely depleted, but the newly developed mine resources have been very limited, and the production capacity has begun to decline, but the demand for titanium dioxide has begun to increase significantly, resulting in the rising price of titanium dioxide.

I believe that both plastic manufacturers and coating manufacturers are familiar with titanium dioxide. Titanium dioxide has a large market share in plastics, papermaking, coatings and other industries by virtue of its excellent white performance. Like the common white products in our lives, titanium dioxide will basically be involved.

However, the titanium dioxide process uses a sulfuric acid process, and most of its functions are to remove impurities in the product, because the impurities seriously affect the application performance, especially the whiteness. Therefore, many paint manufacturers feel that the whiteness value of titanium dioxide is low, the color light is yellow, and the products they make are not bright enough. At this time, knowledgeable manufacturers will choose to add fluorescent brightening agent to improve the whiteness and brightness of the product.

The whitening principle of fluorescent brightening agent and titanium dioxide is different. Titanium dioxide uses physical covering to whiten, which is to use its hiding power to hide the unsightly appearance.

The whitening principle of fluorescent brightening agent is optical whitening, which is emitted by absorbing invisible light and transforming into blue or blue-violet visible light. Blue and yellow are complementary colors to each other to form white, which makes the product appear white and bright.

In addition, because the fluorescent brightening agent increases the reflectance of the product to light, the intensity of the reflected light exceeds the intensity of the original visible light projected on the processed product, so we can see that the whiteness and brightness of the product will increase.

There is another difference between fluorescent brightening agent and titanium dioxide in the amount of addition. The addition amount of titanium dioxide is usually relatively large, while the addition amount of fluorescent brightening agent is very small. Generally, we recommend the addition amount to be about 200-500g is added per ton. For our manufacturers, the cost is almost negligible. Therefore, more and more paint manufacturers now consider adding fluorescent brightening agent for better whiteness of their products.

According to our market experience, the fluorescent brightening agent OB is added to the paint and coating with superior performance.

The following is the technical data for our customers' reference,

Product Name is fluorescent brightening agent OB ,its CAS Number is 7128-64-5

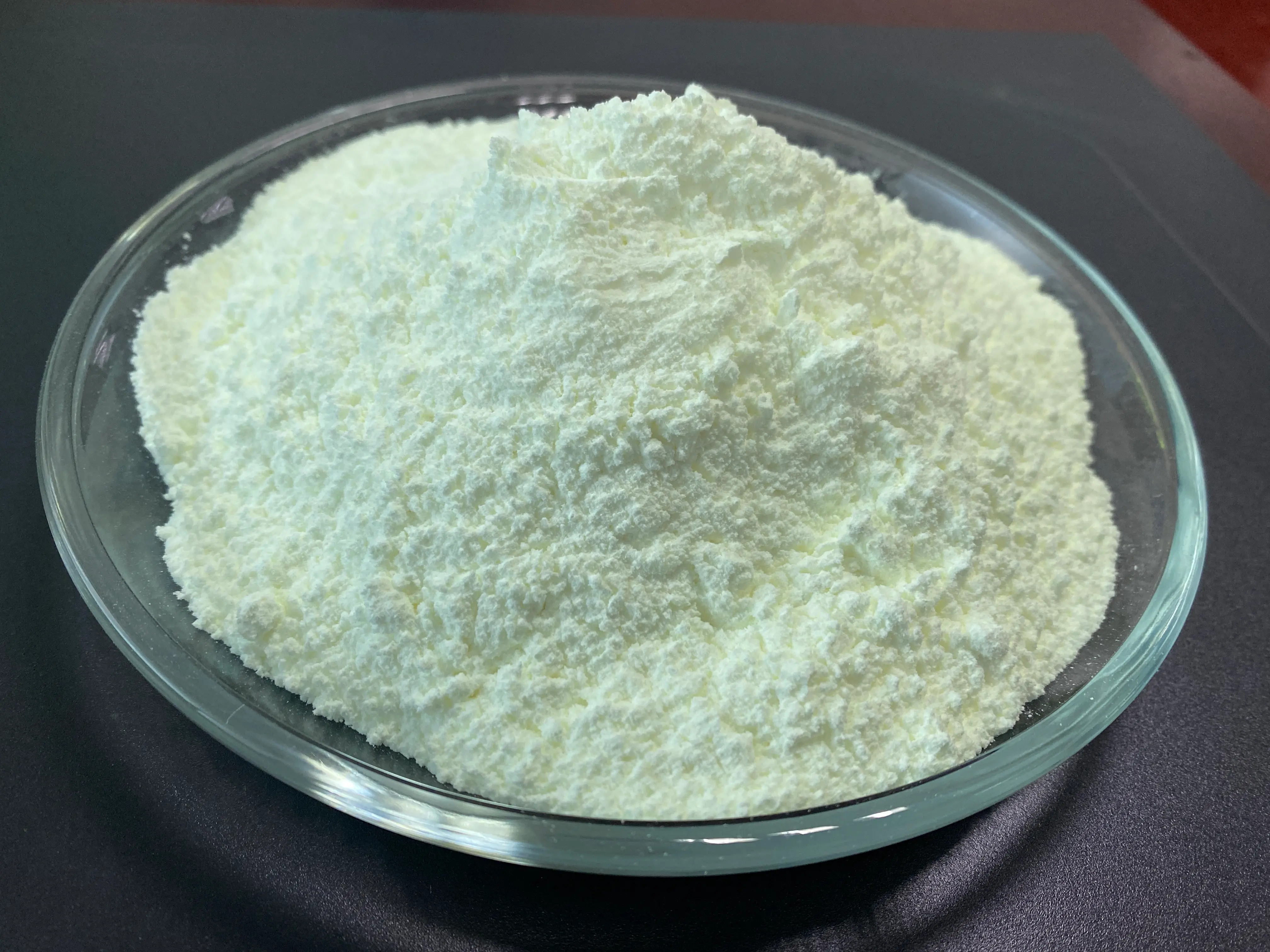

Appearance :Light yellow green crystal powder

Melting Point:196-203℃

Purity:99.4%

Fineness:400 mesh

Transmittance %:450nm ≧98%

500nm ≧98%

Volatile Content:0.2%