What is color masterbatch? Why use color masterbatch?

Color masterbatch, also known as color species, is an aggregate made by uniformly loading a super-constant amount of pigments or dyes in the resin.

Some benefits of using color masterbatch:

1. It is beneficial to maintain the chemical stability of the pigment and the stability of the color;

2. Make the pigment have better dispersibility in the plastic;

3. Protect the health of operators;

4. The process is simple and the color change is easy;

5. The environment is clean and does not stain utensils;

6. Save time and raw materials;

The basic composition of color masterbatch

1. Pigments or dyes

Pigments are divided into organic pigments and inorganic pigments.

2. Carrier

The carrier is the matrix of the masterbatch. The special masterbatch generally chooses the same resin as the product resin as the carrier. The compatibility of the two is the best, but the fluidity of the carrier should also be considered.

3. Dispersant

The dispersant promotes the uniform dispersion of the pigment and no longer agglomerates. The dispersant should have a lower melting point than the resin, have good compatibility with the resin, and have a better affinity for the pigment. The most commonly used dispersants are: polyethylene low-molecular wax, stearate.

4. Additives

Such as flame-retardant, brightening, anti-bacterial, anti-static, anti-oxidation and other varieties, generally do not contain the above additives in the color masterbatch unless the customer requests it.

3. Variety and grade of color masterbatch

The classification methods of color masterbatches are commonly used as follows:

Classified by carrier: such as PE masterbatch, PP masterbatch, ABS masterbatch, PVC masterbatch, EVA masterbatch, etc.;

At present, we generally use PE base material and PP base material on the wire end in a large number of applications.

Classified by purpose: such as injection masterbatch, blow molding masterbatch, spinning masterbatch, etc.

Each species can be divided into different grades, such as:

1. Advanced injection color masterbatch

Used in cosmetic packaging boxes, toys, electrical appliances shells and other advanced products.

2. Ordinary injection color masterbatch

Used for general daily-use plastic products, industrial containers, etc.

3. Advanced blown film masterbatch

Used for blow molding coloring of ultra-thin products.

4. Ordinary blown film masterbatch

Used for blow molding and coloring of general packaging bags and woven bags.

5. Spinning masterbatch

It is used for spinning and coloring of textile fiber. The masterbatch has fine particles, high concentration, strong coloring power, good heat resistance and light resistance.

6. Low-grade color masterbatch

Used to manufacture low-grade products that do not require high color quality, such as trash cans, low-grade containers, etc.

The technical requirements of color masterbatch are very strict. The commonly used color masterbatch technology is a wet process. The color masterbatch is made by water-phase grinding, phase inversion, washing, drying, and granulation. Only in this way can the product quality be guaranteed. In addition, while the pigment is being ground, a series of masterbatch technology testing items should also be carried out.

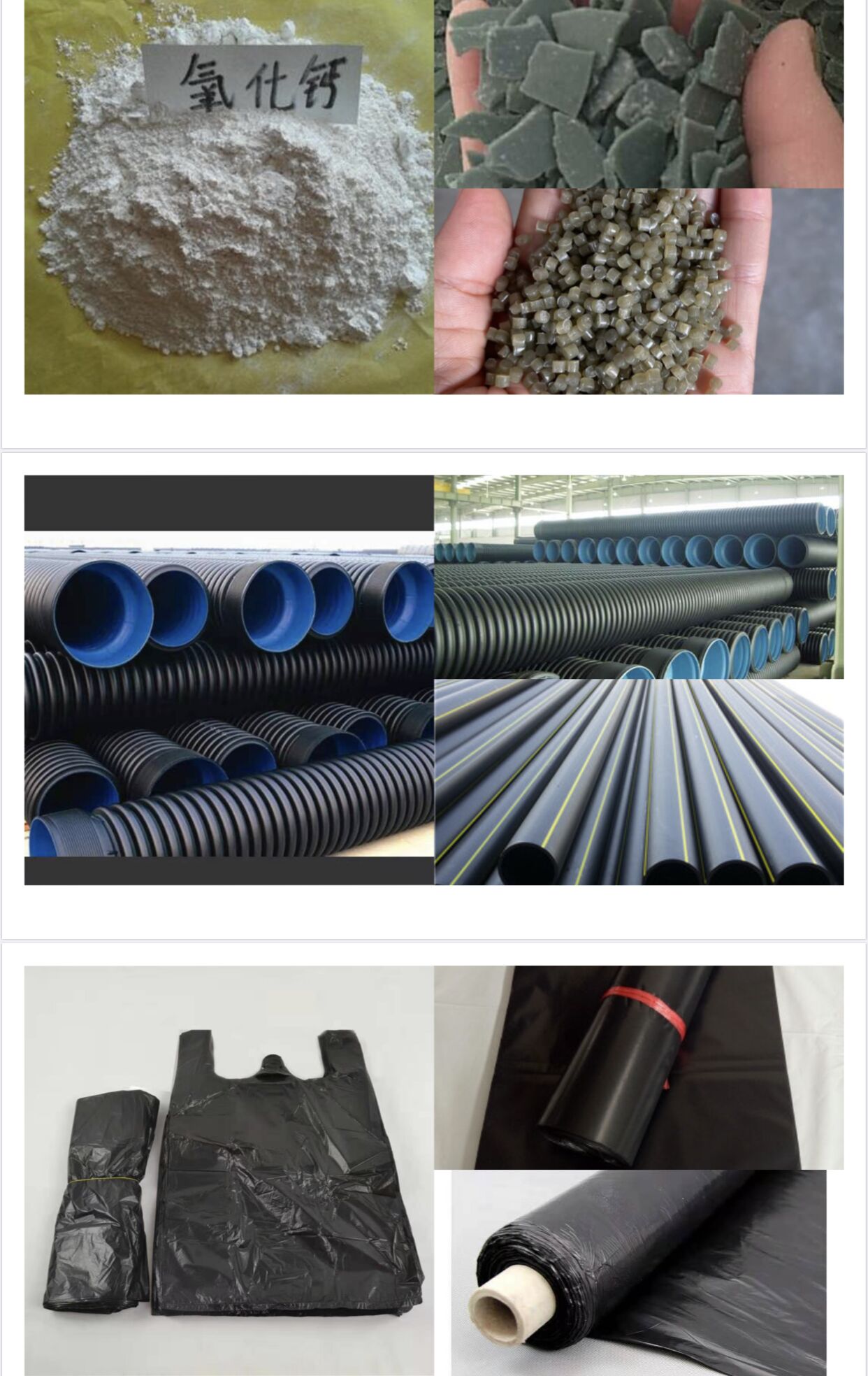

RAYTOP CHEMICAL is the professional manufacturer of kinds masterbatch from the year 2000.Our leading products are as follows,

Black masterbatch

White masterbatch

Desiccant/Defoaming masterbatch

Filler masterbatch

Color masterbatch

Optical brightener masterbatch

As we all know, the African market is one of the most promising plastic markets in the world today. This is a continent with huge economic potential. In some relatively highly concentrated developed urban areas in Africa, the number of people participating in industrial production is rising and growing. The population growth has driven the rapid economic development of the African region, and the subsequent regeneration industry has also undergone rapid changes. At present, the African market has become the main export market for the masterbatch industry. We hope that more and more African friends can visit our factory.