What is the optical brightener ?

Optical brightener OB-1 is the product with the best heat resistance among all optical brightener products. It not only has a high decomposition temperature, good whiteness, and a small amount (generally 25~300 mg/kg), but it also has good properties with additives in plastic .It is mainly used for the whitening of polyester resin, polyester fiber, ordinary plastics and engineering plastics. The three process routes reported in this article have been tested in the laboratory and can be used for the production of products with different quality requirements.

Today we will show you how to make optical brightener OB-1 ,there are 3 ways to produce optical brightener OB-1

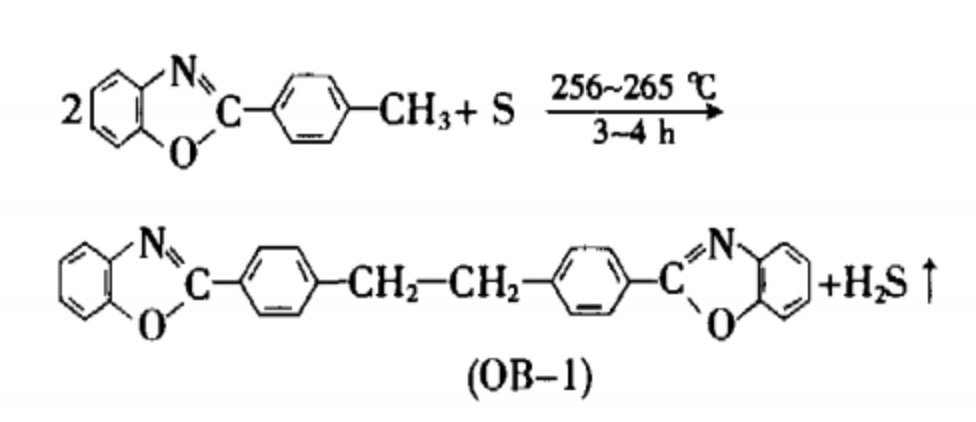

1 Sulfur process make optical brightener OB-1

Raw materials: sulfur powder, 4-methylphenylbenzoxazole, xylene, DMF (N,N-dimethylformamide), NP (N-methylpyrrolidone), all industrial products.

Synthesis:The synthesis of the process includes three parts: vulcanization, desulfurization, and refining.

(1) Vulcanization

Put 4-methylphenylbenzoxazole and sulfur alternately into the vulcanizing kettle at a mass ratio of 1:2~2.5, and heat to 150℃, start stirring, continue heating to 240℃, turn on the H2S absorption device, at 255~265 The reaction temperature is within the range of ℃ for 3 to 4 hours, the temperature is cooled to 160 ℃ at the end of the reaction, a certain amount of xylene is slowly added dropwise, and the material liquid is put into the desulfurization kettle at 120 ℃.

(2) Desulfurization

Heat the liquid in the desulfurization kettle to reflux for 1 hour, and filter while it is hot when the temperature is lowered to 100°C; put the filter cake into the desulfurization kettle, add a certain amount of xylene and heat to reflux for 1 hour, cool to 100°C and filter while it is hot, repeat 3 ~4 times, the last time it was spin-dried with a centrifuge to obtain crude optical brightener OB-1.

(3) Refining According to requirements, the crude product can be refined with DMF or NP.

The production method is simple in process, but has the disadvantages of low yield (50%), large pollution, and high temperature required for production. At present, there are not many domestic manufacturers using this method, but the quality of the products produced by this method is relatively good, basically comparable to those imported from abroad. It should be noted in production that after the vulcanization, the temperature should be cooled quickly, and the purity of the sulfur powder should be high, and the water content (mass fraction) must be below 0.5%. It is best to use sublimated sulfur powder.

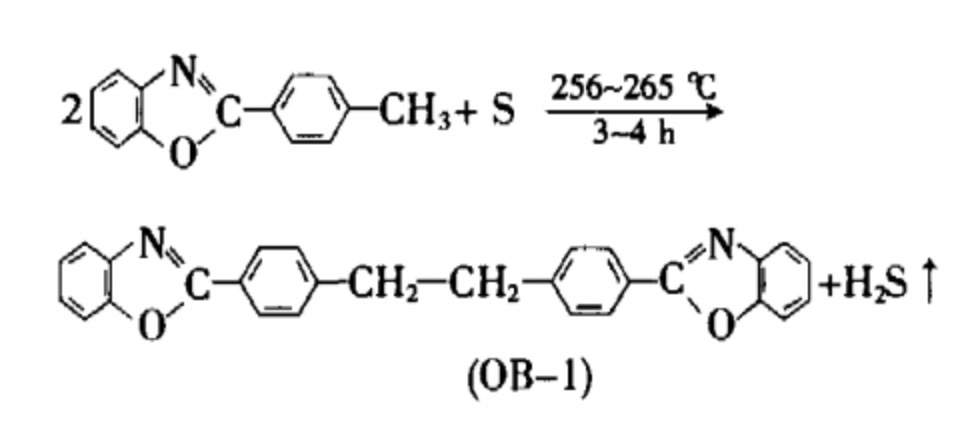

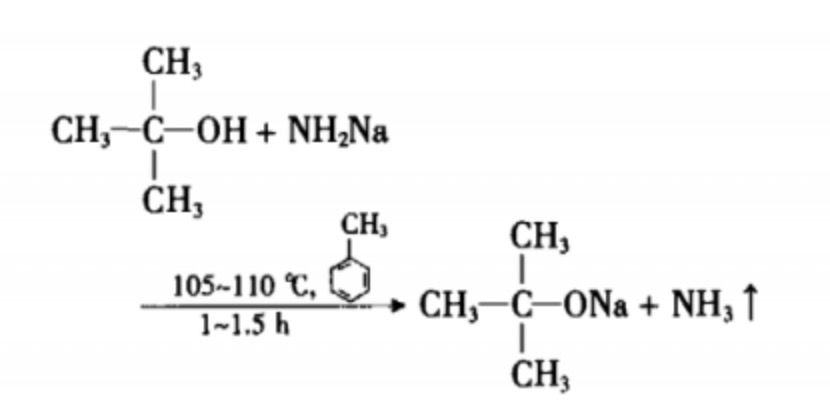

2 Sodium tert-butoxide method make optical brightener

Raw material:Sodium amide, tert-butanol, p-chloromethylphenyl benzoxazole, toluene, DMF, NP are all industrial products.

Synthesis:The synthesis of the process includes three steps of catalyst preparation, synthesis and refining.

(1) Preparation of sodium tert-butoxide

The synthesis reaction formula of sodium tert-butoxide is as follows:

Add toluene, sodium amide, and tert-butanol into the catalytic kettle in a certain proportion in the order of the front and back. After sealing, turn on the stirring and heating, react at 105~110℃ for 1~1.5h, then cool to below 20℃, add a small amount DMF diluted for use

(2) Synthesis:The reaction formula for synthesizing OB-1 by sodium tert-butoxide method is:

Put the p-chloromethyl phenyl benzoxazole and DMF into the synthesis kettle in a certain ratio. When the temperature drops below 0℃, quickly add the prepared sodium tert-butoxide, and fully react for 1~1.5h. , Add a small amount of glacial acetic acid to adjust the pH to about 7, press filter, filter cake, that is, crude optical brightener OB-1.

(3) Refined

According to the need for purity. Recrystallize with DMF or NP. The production process is simple, the raw materials are easily available, the yield is high (79%), and it is pollution-free. It is an environmentally friendly process. At present, 4 to 5 domestic manufacturers adopt this process, and the OB-1 cis structure produced is more than the trans structure. Structure, poor fluorescence, good whitening effect, suitable for whitening common plastics and engineering plastics. In the synthesis, the quality of sodium tert-butoxide directly affects the yield of the product, the highest temperature during the synthesis reaction directly affects the appearance, color and fluorescence intensity of the optical brightener OB-1 product, the entire reaction of the process and the main raw materials used for water content The requirements are particularly strict and must be less than 0.5%.

3 Oxazole aldehyde method make optical brightener OB-1

Synthesis process: The synthesis process of OB-1 produced by oxazole aldehyde method mainly includes three steps of esterification, condensation and recrystallization.

(1) Esterification:

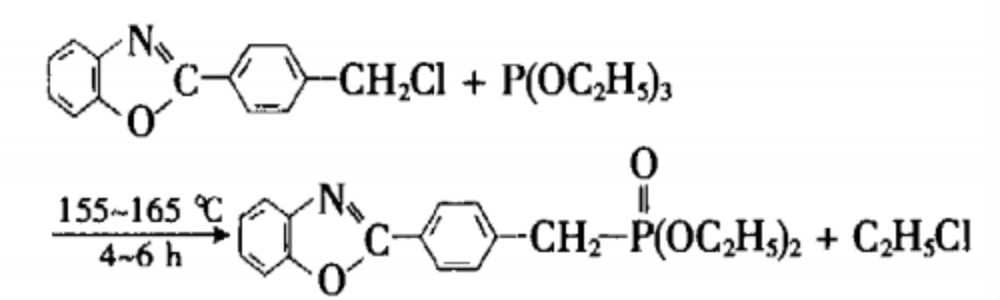

Put the p-chloromethyl phenyl benzoxazole and triethyl phosphite into the esterification kettle at a ratio of 1:1.2, and then heat up to 155~160°C for 4~6 hours. The excess triethyl phosphite was distilled off under reduced pressure to obtain a light yellow ester compound. The reaction formula is:

(2) Condensation

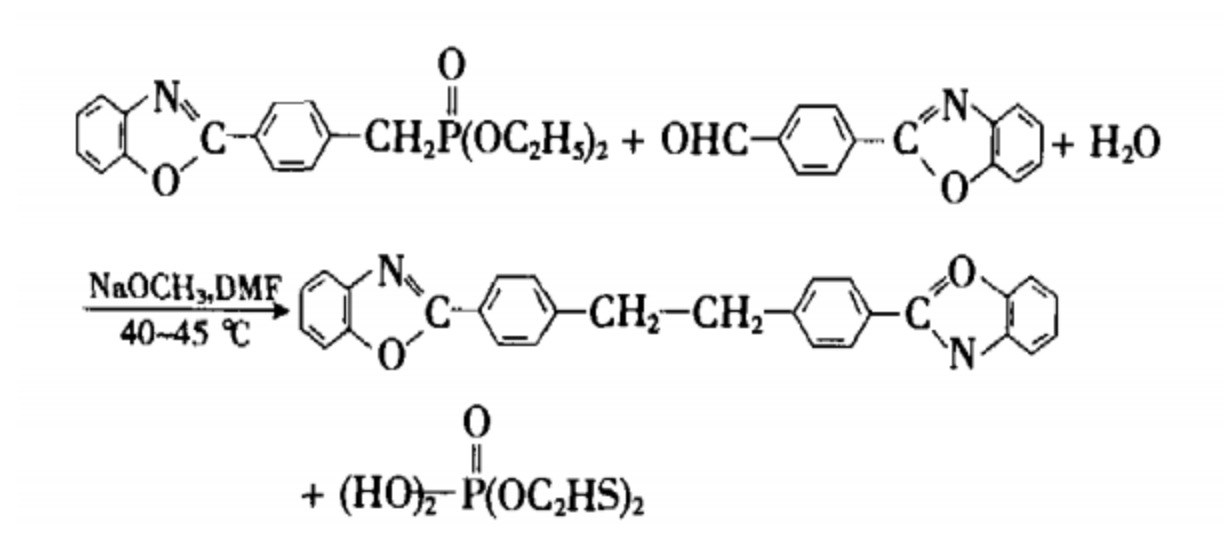

The reaction formula of condensation is:

Weigh the oxazole aldehyde in the same amount as the p-chloromethylphenyl benzoxazole, add it to the esterified product, then add an appropriate amount of DMF, heat up to the material completely dissolved, and then cool down at 40~45℃ Add a solution of sodium methoxide (29%) dropwise. After the dropwise addition, the temperature is raised to 60°C, reacted for 2~3h, cooled and filtered under pressure to obtain crude optical brightener OB-1. The process is simple, pollution-free, and has a high yield (81%). It is the process adopted by most domestic manufacturers. The OB-1 trans structure produced by this process is more than the cis structure, the fluorescence is good, and the product has a beautiful appearance. When used for polyester chemical fiber and polyester polyester, the use effect is better than the optical brightener OB-1 produced by the above two processes.

Optical brighteners have very high application fields, which means that optical brighteners have high market value.

Semi continuous method for making optical brightener

The invention relates to a semi continuous method for making optical whitening agent, which belongs to the field of production methods of optical whitening agent; Sodium 4,4 '- bis (4,6-dichlorotriazine-2-amino) stilbene-2,2' - disulfonic acid was obtained by adding acid binding agent at a uniform rate through the molar ratio of cyanuric chloride: 4,4-diaminostilbene-2,2-disulfonic acid until the amino group disappeared; According to the molar ratio of 4,4 '- bis (4,6-dichlorotriazine-2-amino) stilbene-2,2' - disulfonic acid sodium: aniline, the reaction is carried out under the control of acid binding agent and temperature rise, the amino group disappears, and the two-step condensation product is obtained for standby; According to the molar ratio of diethanolamine: two-step condensation product, the obtained three-step condensation product is reacted with acid binding agent and sent to the pipeline reactor to obtain the reaction liquid. After cooling, suction filtration, impurity removal, desalination and concentration, the finished product is obtained. This method can not only ensure the conversion of reaction, but also stabilize the quality of optical brightener, improve production efficiency and increase the production capacity per unit time, Reduce the comprehensive production cost and improve the market competitiveness of enterprises.

How to make Optical brightener VBL?

This whitening agent was produced by manufacturers in China in the 1960s. The product output was large. It was first used for whitening cellulose and fabrics, and then mainly for whitening paper. There are several common problems with optical brightener VBL during use:

The optical brightener VBL has few sulfonic acid groups in its molecule and its water solubility is not ideal, which makes it difficult to melt.

Optical brightener VBL is easy to precipitate when used in solutions with low pH value.

The yellowing point of optical brightener VBL is low, so it is limited to be used in products requiring high whitening.

There are many amorphous products in VBL products, and the appearance changes from light yellow to green, which affects the whiteness of the products.

The finished VBL contains sodium sulphate, and the inconsistent fineness is easy to cause dust flying and chemical material agglomeration. Although the optical brightener VBL has the above shortcomings, it still has an irreplaceable position because of its advantages in price, performance and application range.

There are three main raw materials for the synthesis of optical brightener VBL: DSD acid, cyanuric chloride, aniline and ethanolamine. The production method is three-step condensation.

The first step of condensation: add water and ice in the condensation kettle, add dye homogenizer o aqueous solution and industrial hydrochloric acid, add cyanuric chloride, stir for 1 hour, add DSD acid for 3-4 hours, neutralize with sodium carbonate solution, control pH value and measure amine group. After the amine group disappears, the first step of condensation is completed.

The second step of condensation: inject the reaction material of the first step into the second condensation kettle, add aniline, slowly raise the temperature to 15-20 ℃, start neutralization with sodium carbonate, measure the amine value when the temperature reaches 30-40 ℃, the amine value disappears, and the second step of condensation is completed.

The third step of condensation: inject the reaction material of the second step into the third condensation kettle, add ethanolamine, raise the temperature to 75 ℃, add ammonia, raise the temperature to about 100 ℃ in the closed reaction, keep the temperature for 1-2 hours, cool to 35-40 ℃, add water and stand for 2 hours, transfer it to the acid analysis kettle after filtration, heat it to 85 ℃, add industrial hydrochloric acid for acid analysis, and enter the kneader after dehydration of the lower filter cake, Add proper amount of soda, beating and spray drying. The finished optical brightener VBL was obtained.

The liquid finished product of optical brightener VBL is prepared. The sulfonic acid filter cake is added to the reactor, urea is added to start stirring, ammonia is added to neutralize, an appropriate amount of water is added to ensure the strength up to 46 phr, then the closed temperature is raised to 90 ℃, it is reduced to room temperature, and a certain amount of CMC is added to make the dispersion reach the specified strength of 45 phr.