What is Optical Brightener OB-1?

Optical Brightener OB-1, also known as 2,2’-(1,2-ethenediyldi-4,1-phenylene)bisbenzoxazole, is a benzoxazole-based fluorescent whitening agent. It belongs to the family of high-temperature-resistant optical brighteners and is especially suitable for use in engineering plastics and polyester fibers.

Chemical Information

Chemical Name: 2,2’-(1,2-ethenediyldi-4,1-phenylene)bisbenzoxazole

CAS Number: 1533-45-5

Molecular Formula: C28H18N2O2

Molecular Weight: 414.46 g/mol

Chemical Structure: Biphenyl-bisbenzoxazole skeleton

Key Characteristics

High melting point (>350°C), suitable for high-temperature processing

Strong blue-violet fluorescence

High chemical stability in polymer systems

Compatible with most thermoplastic resins

Introduction of fluorescent brightener OB-1(Optical brightener agent OB-1)

CI:393

CAS:1533-45-5

Chemical name: stilbene dibenzoxazole

Molecular formula: c28h18n2o2

Molecular weight: 414.4547

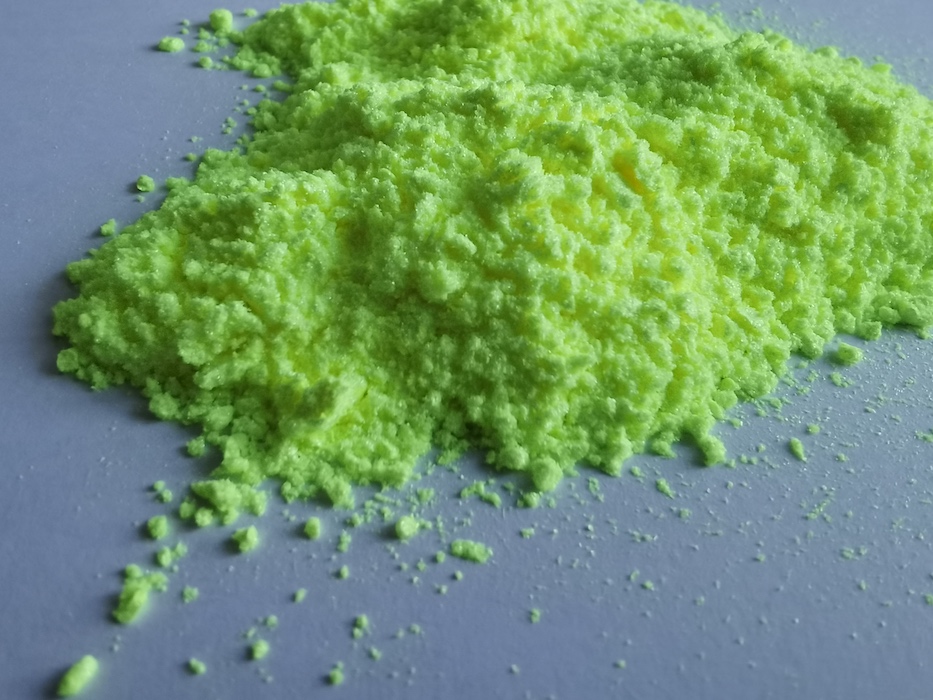

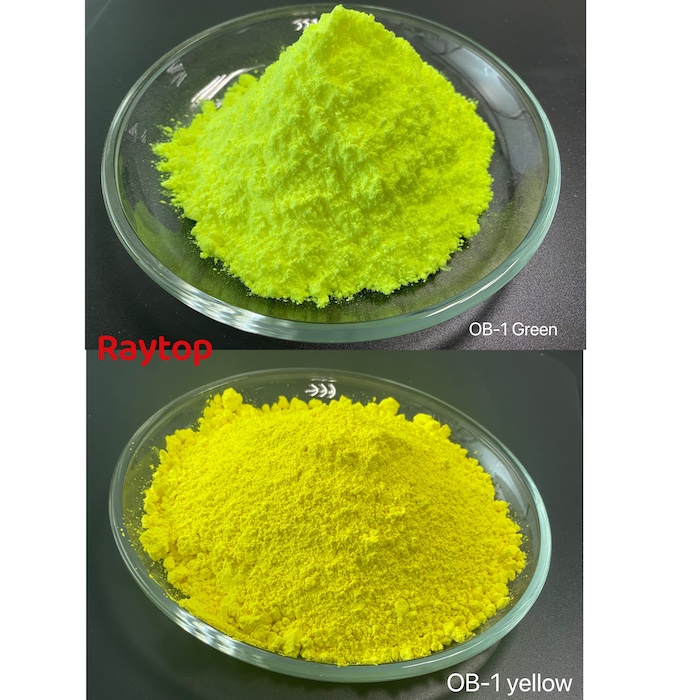

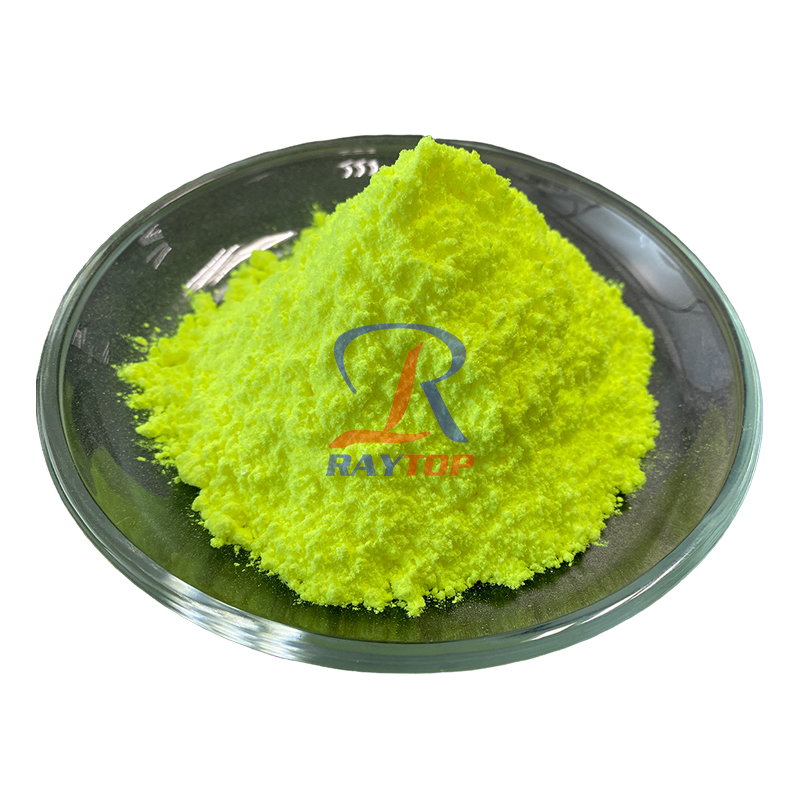

Properties: bright yellow green crystalline powder, insoluble in water, odorless, stable performance, melting point 355 ℃ - 360℃

Technical conditions:

Color light: blue light or blue violet light

Maximum absorption spectral wavelength: 374nm, with strong fluorescence and emission wavelength of 434nm

Content: ≥ 98.5%

Fineness: ≥ 300 mesh

UV absorption: ≥ 2000

Volatile matter: ≤ 1%

Ash content: ≤ 1%

Optical Brightener OB-1 Technical Data Sheet (TDS)

The following TDS data provides a reference for manufacturers using OB-1 in plastics and fibers:

| Property | Data |

|---|---|

| Appearance | Bright yellow-green crystalline powder |

| Melting Point | 350–355 °C |

| Assay (Purity) | ≥98.5% |

| Volatile Content | ≤0.5% |

| Ash Content | ≤0.3% |

| Specific Gravity | 1.38 g/cm³ |

| Maximum Absorption Wavelength (λmax) | 374 nm |

| Maximum Emission Wavelength (λem) | 434 nm |

| Heat Resistance | Up to 360 °C |

| Solubility | Insoluble in water, soluble in organic solvents |

| Recommended Dosage | 0.01–0.05% (100–500 ppm) depending on polymer |

| Stability | Excellent light and weather resistance |

Applications of Optical Brightener OB-1

1. Polyester (PET, PBT)

Improves brightness of virgin and recycled PET resins.

Extensively used in PET bottle recycling, polyester fibers, and films.

2. Polypropylene (PP)

Enhances whiteness of injection-molded and extruded PP products.

Widely used in household appliances, automotive parts, and packaging.

3. Polyamide (PA6, PA66)

Suitable for nylon fibers and engineering plastics.

Maintains stability at nylon processing temperatures.

4. Polycarbonate (PC)

Excellent compatibility and resistance to high processing heat.

5. ABS, PS, EVA, PVC

OB-1 is compatible with most thermoplastics, improving overall appearance.

6. Engineering Plastics & Masterbatch

Common additive in whitening masterbatch and plastic compounding industries.

Introduction to OB-1 features:

With high temperature resistance, it is the fluorescent whitening agent for plastics with the widest application range and the largest sales so far. The public lover in the whitening agent is especially large in industries such as building materials, chemical fiber and polyester staple fiber.

Excessive use has poor weather resistance and easy precipitation, and the addition amount shall not exceed the peak value.

High fluorescence intensity, suitable for compounding with other models to produce synergistic effect.

Dosage of OB-1 method:

PVC and PP recycled materials are powerful whitening tools. The addition amount of profile is about 230g per ton, the granulation of general recycled materials is about 500-700g, and the chemical fiber plant is about 450g per ton.

Whitening and brightening of polypropylene plastics, rigid PVC, ABS, EVA, polystyrene, polycarbonate, etc

The addition proportion shall be determined according to the old and new raw materials.

The addition amount of color masterbatch is between 3kg and 10kg per ton.

The whitening agent OB-1 is equivalent to 0.01-0.05% of the weight of plastic or polyester particles, and can be fully mixed with materials before molding and processing of various plastic products or polyester fiber drawing.

Optical Brightener OB-1 Dosage in Different Plastics

Plastic Type Processing Temperature (°C) Recommended Dosage (%) Main Applications Key Considerations Polyolefins (PE, PP) 180–240 0.01–0.05 Films, injection molding, fibers High crystallinity materials require attention to dispersion; avoid high-temperature interactions with antioxidants causing yellowing. Polyesters (PET, PBT) 250–280 0.005–0.03 Fibers, bottle-grade PET, engineering plastics Lower dosage for fibers (0.005–0.02%); avoid prolonged processing due to thermal decomposition. Polyamides (PA6/PA66) 260–290 0.01–0.04 Fibers, engineering plastics Control humidity for hygroscopic materials; avoid contact with metal ions (e.g., Mg²⁺, Ca²⁺). Polycarbonate (PC) 280–320 0.005–0.02 Optical components, electronic housings Strict dosage control to prevent thermal degradation; may reduce toughness—optimize via small-scale trials. ABS 200–240 0.01–0.05 Automotive parts, appliance housings Test compatibility with flame retardants and lubricants; ensure uniform dispersion in thick-walled products. PVC 160–200 0.01–0.03 Pipes, films, artificial leather Prevent additive migration by controlling temperature; avoid lead-based stabilizers. Polystyrene (PS) 180–220 0.01–0.03 Transparent packaging, stationery Ensure dispersion in high-impact PS (HIPS); test stability with flame retardants. Supplementary Notes

General Considerations:

Thermal Stability: OB-1 degrades at temperatures above ~300°C; adjust dosage for high-temperature processes.

Dispersion: Ensure thorough mixing in high-viscosity materials (e.g., PC, PA) to avoid localized overheating or yellowing.

Synergistic Effects: Combine with titanium dioxide or other brighteners for enhanced performance.

Safety/Compliance: Meets RoHS and REACH standards; avoid contact with strong oxidizers.

Application Tips:

Start with mid-range dosages (e.g., 0.02–0.03%) and adjust based on whiteness results.

Conduct long-term aging tests (light exposure, humidity) to validate durability.

Consult supplier technical data sheets (TDS) for product-specific recommendations.

The Optical Brightener OB-1 TDS demonstrates why this agent is the go-to choice for whitening polyester, polypropylene, nylon, and other engineering plastics. With its high thermal stability, superior whitening effect, and compatibility across polymer systems, OB-1 is a critical additive for both virgin and recycled plastics.

For manufacturers in packaging, textiles, and engineering materials, using Optical Brightener OB-1 not only improves product aesthetics but also ensures competitive market positioning. With global demand on the rise, OB-1 remains one of the most valuable whitening solutions in the plastics industry.

264.jpg)