In the ever-evolving world of textile and paper manufacturing, appearance matters—immensely. Whiteness, brightness, and optical vibrancy are often the unspoken but vital hallmarks of quality. At the center of this pursuit lies a class of additives known as optical brighteners or fluorescent whitening agents (FWAs). Two of the most commonly used compounds in this category—OB-1 and CBS-X—are often compared for their performance, compatibility, and application effectiveness. But are they interchangeable? What sets them apart? And how do they interact with different substrates such as textile fibers and paper pulp?

This article dissects the nuanced differences between OB-1 and CBS-X from a chemical, industrial, and practical standpoint—drawing on scientific studies, empirical data, and the first-hand experience of seasoned manufacturers like Shandong Raytop Chemical Co., Ltd.

Understanding the Role of Optical Brighteners

Optical brighteners are chemical compounds that absorb ultraviolet (UV) light and re-emit it in the blue visible spectrum. This fluorescence counters yellowing and makes materials appear cleaner, whiter, and brighter. They do not remove stains; rather, they trick the eye into perceiving greater whiteness.

Table 1: General Properties of OB-1 and CBS-X

| Property | OB-1 | CBS-X |

|---|---|---|

| Chemical Family | Stilbene Benzoxazole Derivative | Stilbene Sulfonic Acid Derivative |

| CAS Number | 1533-45-5 | 27344-41-8 |

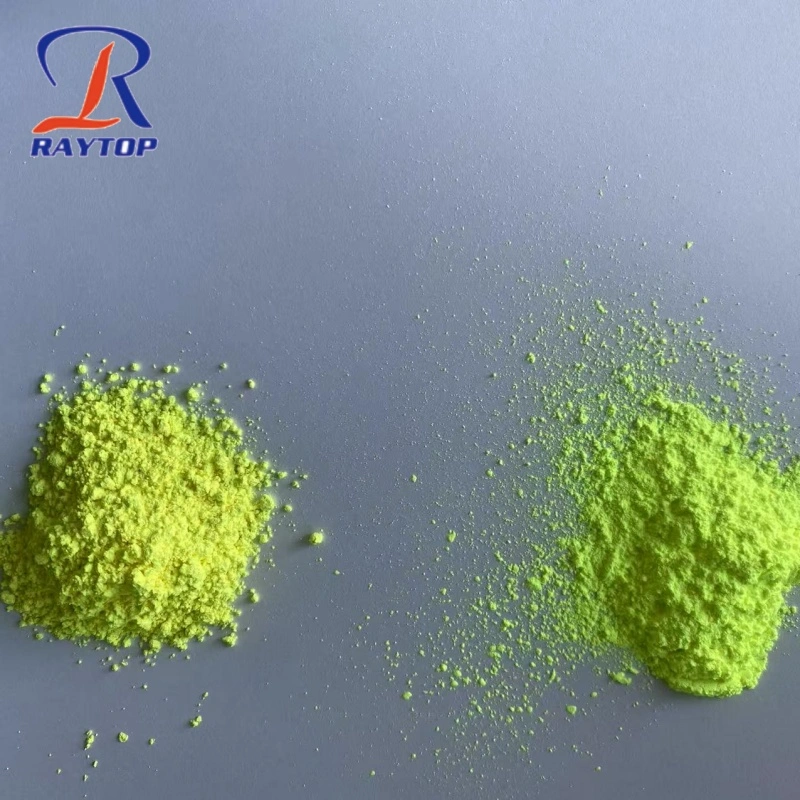

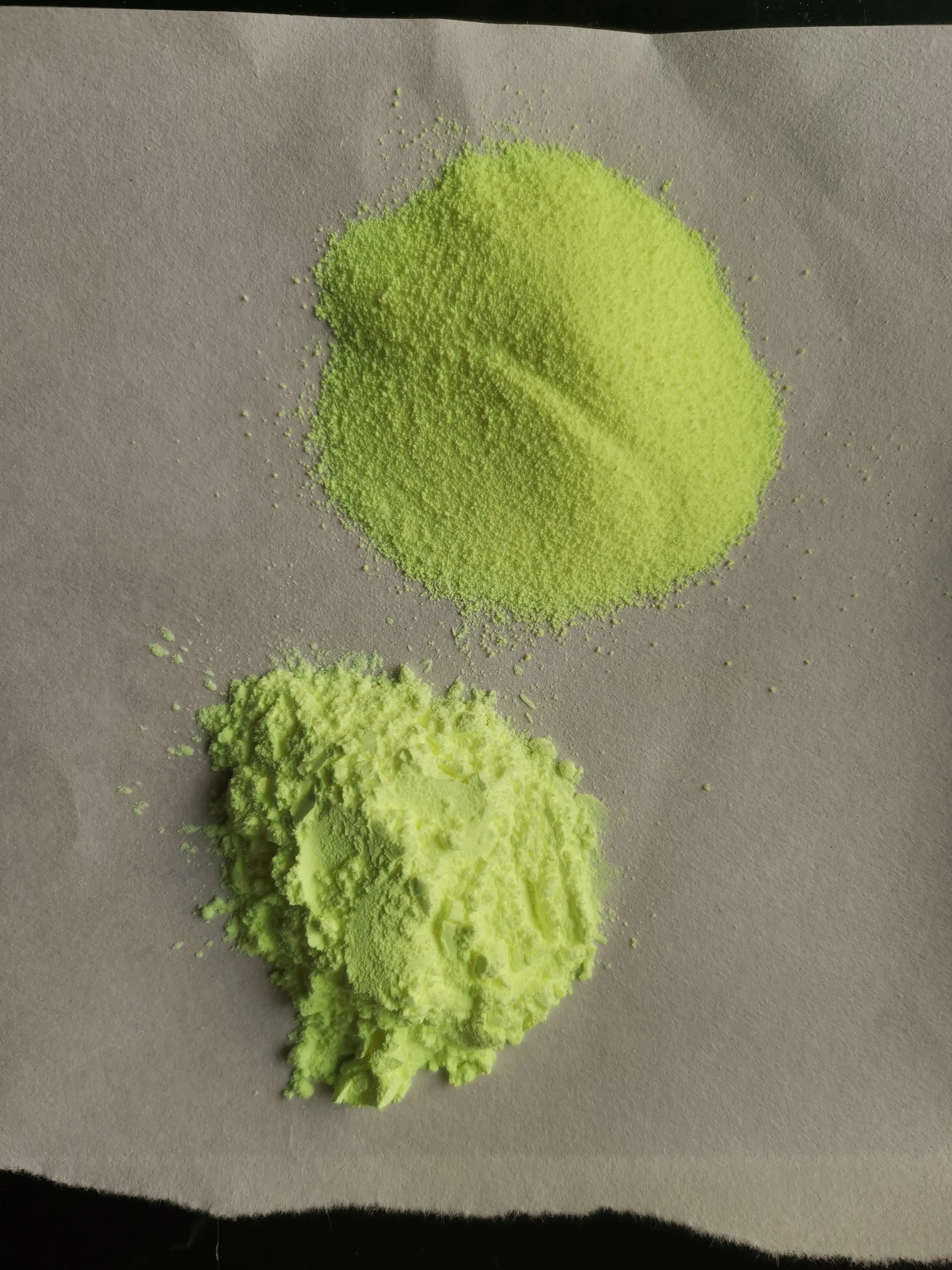

| Appearance | Yellowish-green powder | Yellowish granular powder |

| Solubility in Water | Insoluble | Highly soluble |

| Fluorescence Color | Greenish-blue | Bright blue |

| Recommended Use | Polyester, plastics, fibers | Paper, detergents, cotton textiles |

| Processing Temperature | Up to 300°C | Below 120°C |

OB-1: High-Temperature Brightness for Synthetic Resilience

Let’s begin with OB-1, or 2,2’-(1,2-ethenediyl)bis[5-tert-butylbenzoxazole]. This compound is favored primarily in polyester and engineering plastics, where high-temperature processing is routine. Optical Brighteners OB-1 boasts excellent thermal stability, making it a go-to choice for synthetic fiber spinning, especially when working with polyester, nylon, or PET.

But what really distinguishes OB-1 is its greenish-blue fluorescence under UV light, which creates a cool-tone effect. While it does not dissolve in water, it disperses efficiently within polymer matrices.

However, OB-1 has a downside: it can be relatively slow to show immediate whitening effect, particularly in low-temperature processes. This makes it less ideal for detergents or aqueous applications. Still, in plastics and high-heat textile processing? It’s hard to beat.

Research Insight

According to a 2023 study published in the Journal of Industrial Textiles, OB-1 showed up to 27% higher whiteness index in polyester fiber when compared to other brighteners under similar heat conditions.

CBS-X: Water-Soluble Brilliance for Paper and Detergent Excellence

Switching gears, CBS-X (C.I. Fluorescent Brightener 351) is often the star in detergents and paper manufacturing. With superior water solubility and a neutral pH profile, Optical brighteners CBS-X is perfectly suited for low-temperature, aqueous environments. It’s also the brightener of choice in laundry detergents, as it provides instant brightness enhancement when dissolved in washing water.

CBS-X’s bright blue fluorescence corrects yellowing and boosts visual cleanliness—particularly effective on cellulose-based substrates like cotton and paper.

From a production standpoint, CBS-X is easier to blend and homogenize in formulations due to its high solubility. But it lacks thermal resilience. High temperatures above 120°C can degrade its fluorescence, limiting its use in heat-intensive processes.

Table 2: Comparative Application Suitability

| Application Area | OB-1 Suitability | CBS-X Suitability |

|---|---|---|

| Polyester Textiles | ★★★★★ | ★★☆☆☆ |

| Nylon Fibers | ★★★★☆ | ★☆☆☆☆ |

| Paper Whitening | ★★☆☆☆ | ★★★★★ |

| Detergent Formulas | ☆☆☆☆☆ | ★★★★★ |

| Plastic Masterbatches | ★★★★★ | ★☆☆☆☆ |

| Low Temp. Textiles | ★☆☆☆☆ | ★★★★☆ |

Molecular Behavior and Compatibility

From a chemist’s point of view, the disparity between OB-1 and CBS-X is deeply rooted in their molecular structure and polarity.

OB-1 is hydrophobic, preferring nonpolar environments like synthetic polymers.

CBS-X, on the other hand, is anionic and hydrophilic, making it water-loving and ideal for cellulose-based or aqueous applications.

This inherent difference affects not only the processability of the two agents but also their retention and durability post-treatment.

Environmental Considerations: Biodegradability & Wastewater Impact

In today’s eco-conscious manufacturing climate, environmental impact is non-negotiable. CBS-X, despite its performance in detergents, has raised questions due to its persistence in wastewater. Studies have shown that residual CBS-X can linger in effluents, leading to bioaccumulation in aquatic environments.

OB-1, by contrast, is less likely to leach into water bodies, but it’s also non-biodegradable and potentially problematic during polymer recycling.

Table 3: Environmental Comparison

| Property | OB-1 | CBS-X |

|---|---|---|

| Water Solubility | No | Yes |

| Biodegradability | Poor | Moderate |

| Aquatic Toxicity Risk | Low | Medium-High |

| Wastewater Treatment Concern | Low | High |

| Recyclability with Substrate | Compatible | Less compatible |

Performance in Real-World Industry: Raytop's Perspective

At Shandong Raytop Chemical Co., Ltd., we've spent nearly two decades perfecting and supplying high-performance optical brighteners across the globe. With six modern workshops and a dedicated R&D team, we’ve seen firsthand how OB-1 and CBS-X play distinct roles in our clients' success stories—from India’s polyester fiber markets to Europe’s eco-certified detergent manufacturers.

Why Clients Choose Raytop OB-1:

High-temperature resistance up to 300°C

Excellent dispersion in polymer resins

Minimal dosage for maximum brightness

Consistent performance in recycled plastics

Why Clients Choose Raytop CBS-X:

Instant solubility in water-based systems

Excellent whitening effect on paper and cotton

Neutral pH compatibility

Low foaming and high retention

And let’s not overlook one of the most underestimated advantages: batch-to-batch consistency. At Raytop, we use high-performance liquid chromatography (HPLC), whiteness meters, and melting point analyzers to ensure our customers get repeatable, reliable results.

Subtle But Significant Use Case Differences

It’s tempting to lump OB-1 and CBS-X into the same "brightener basket," but that’s a bit like saying all paints are the same because they’re colorful. The truth lies in the subtle divergences—the kind of nuances that only surface when things go wrong: yellowing post-wash, poor heat resistance, uneven dispersion, and even regulatory non-compliance.

While OB-1 thrives under pressure (and heat), CBS-X is the delicate artist of the brightener world—flourishing in mild, aqueous, cellulose-friendly environments.

A Word on Innovation and the Road Ahead

As demand for biodegradable polymers and eco-label detergents continues to rise, new generations of optical brighteners are being developed with improved environmental profiles. At Raytop, we are actively investing in next-gen FWAs that retain high performance while meeting OECD biodegradability standards.

Conclusion: Choose Brightly, Choose Wisely

In the OB-1 vs. CBS-X debate, there’s no “winner”—only a clearer understanding of their distinct superpowers. OB-1 is the thermally robust warrior for polymers and synthetic textiles. CBS-X is the aqueous wizard for detergents and paper.

So how do you choose?

Well, you start by identifying your substrate, your process conditions, and your end-user expectations. And if you're still unsure, Shandong Raytop Chemical Co., Ltd. is just a message away—with a technical team that has not only the answers but the real-world experience to back them up.

Because at the end of the day, it’s not just about brighter products. It’s about brighter decisions.

About Shandong Raytop Chemical Co., Ltd.

Founded in 2006 and headquartered in Jinan City, Raytop Chemical is a pioneer in optical brightener solutions. Our products have illuminated manufacturing processes across Europe, Asia, Africa, and the Americas, trusted for their quality, consistency, and competitive edge. With three production bases covering 120,000 square meters, Raytop is your global partner for next-level brightness.

Contact us today to discuss how our OB-1, CBS-X, or other additives can support your manufacturing excellence.