EVA is the abbreviation of ethylene-vinyl acetate copolymer. It is a random copolymer composed of non-polar, crystalline ethylene monomer and strongly polar, non-crystalline vinyl acetate monomer (also known as VA).

Compared with PE, EVA introduces vinyl acetate monomer in the molecular chain, which reduces crystallinity, improves flexibility, impact resistance, and improves filler incorporation and heat sealability. The general density is between 0.91 and 0.93. , Good transparency and gloss.

EVA is a thermoplastic polymer, so it can be used in injection molding, extrusion, blow molding, calendering, rotational vacuum thermoforming, foaming, coating, heat sealing, welding and other processing molding processes.

EVA materials have been widely used in shoe materials for a long time. Its blended foamed shoe materials have the properties of softness, good elasticity, shock absorption, chemical resistance, etc., and are widely used in medium and high-end tourist shoes, hiking shoes, slippers, sandals The soles and other aspects.

In terms of shoe materials, EVA foaming process generally has three processes: traditional large flat foaming, small in-mold foaming and injection cross-linking foaming. Among them, molded foaming and injection cross-linking foaming are more used. In recent years, with the development of supercritical foaming technology, EVA materials can also realize the foaming application of this technology.

01 Large foaming of traditional flat panel

Small factories generally use this because the cost of machinery and equipment is relatively low. This process is made of plates, which are then made into products through processes such as punching and edging, but the production efficiency is low and there are many leftovers.

02 Small foam in the mold

In-mold small foaming is also called molded foaming, which is to pelletize the material prepared according to the formula, weigh it and put it into the opened mold, and the foam will look like a shoe. This process presents higher quality in details and higher dimensional accuracy.

The process is divided into primary molded foaming and secondary molded foaming. For example, the PHYLON midsole is EVA secondary molded foaming, which has good dimensional stability and excellent variability, and can be adjusted according to the needs of each sneaker design. Shape the shape into a variety of different styles.

The difficulty of the small in-mold foaming process is the symmetry of the mold and the formula. Otherwise, it is difficult to control the magnification and the hardness at the same time. Process conditions such as temperature, time and pressure also have a great influence on the properties of the material.

03 Injection cross-linked foam

Injection cross-linked foaming has now become the mainstream process for preparing EVA shoe midsoles by large shoe material processing factories. The process is to mix EVA, modifiers, additives, etc. at high speed, extrude and pelletize, and then perform injection molding. Only half the size of the finished midsole.

The high-temperature mold needs to stand for a period of time, otherwise, the EVA midsole will pop out when the mold is opened. Because the mold is much smaller than the actual midsole, the midsole will expand rapidly when it is released from the mold. After the injection molded midsole expands to a larger size, it may shrink during the subsequent cooling process. Therefore, the expansion and contraction process of the injection molding method is more complicated than the compression molding method.

Compared with small in-mold foaming, this process has significant advantages such as high production efficiency and basically no edge material, which can greatly reduce manufacturing costs and make product designs more diversified and functional.

04 Supercritical foaming

The molecular chain of EVA is linear, so it is usually necessary to add a cross-linking agent during the foaming process to lock the gas through the cross-linked structure. Therefore, the supercritical foaming of EVA needs to solve the problem of how to lock the gas.

According to patent documents and some enterprise data, the supercritical foaming process of EVA is basically such a route: cross-linking and pelletizing after banburying and blending, molding to obtain a pre-vulcanized sole, and putting the sole into an autoclave for foaming In the device, a physical foaming agent is introduced into the kettle, and the microporous foaming sole material is obtained by the pressure-reducing method.

The morphological changes of EVA materials: granulation-injection/injection-foaming-sole.

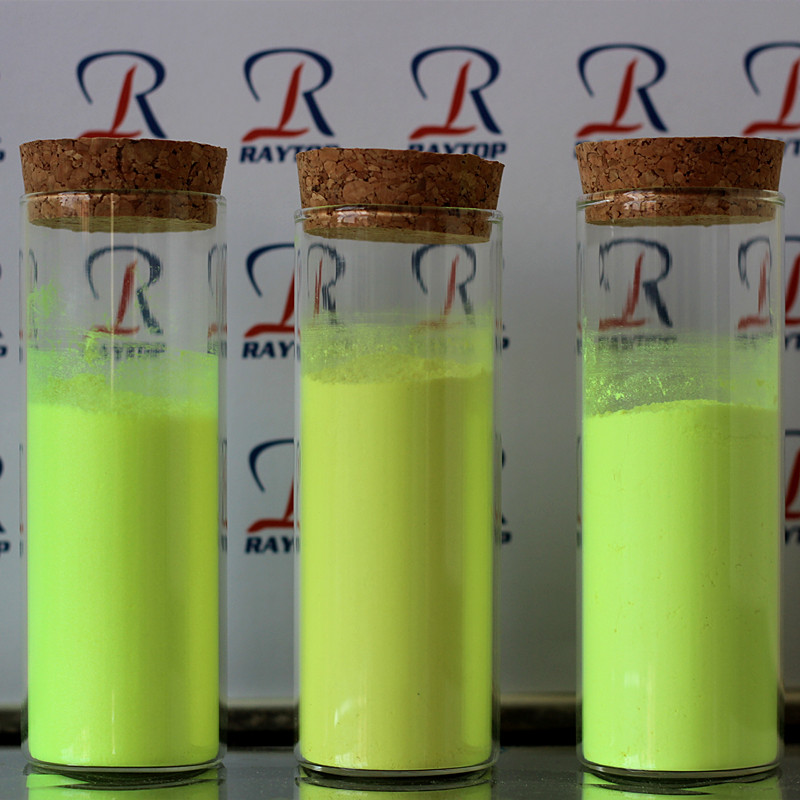

Today's young people have very high requirements for the appearance of shoes, especially the bright white soles, so the optical brightener KCB has played an important role. For EVA foamed soles, whether in terms of theory or practical experience, the optical brightener KCB is the most suitable. The following is the index of optical brightener KCB 367.

05 Optical Brightener KCB 367 for EVA

Product Cate: Optical Brightening Agent For Plastic

Product Name: Optical Brightener KCB

Chemical Name: 1,4-Bis(2-benzoxazoly)naphthalene

CAS No.: 5089-22-5

C.I. No. :367

Molecular Formula:C24H14N2O2

Molecular Weight: 362

Properties:Comprehensive application field, good compatibility with all kinds of plastic, excellent stability under all kinds of climate.

Appearance:yellow crystalline powder

Melting Point:210-212°C

Purity:≥99%

Maximum UV Absorption Spectrum:370nm

Application:

mainly be used in whitening of synthetic fiber and plastic products, especially good at whitening of EVA.