What is photoluminescent pigment?

The photoluminescent pigment powder is made by activating alkaline earth aluminate with rare earth elements.

Photolumiescent can glow in darkness for 12 hours continuously after it has absorbed various visible lights for 10-20 minutes. Its luminance brightness and duration is at least 30 times of traditional luminescent materials represented by ZnS:Cu, and can be used repeatedly.

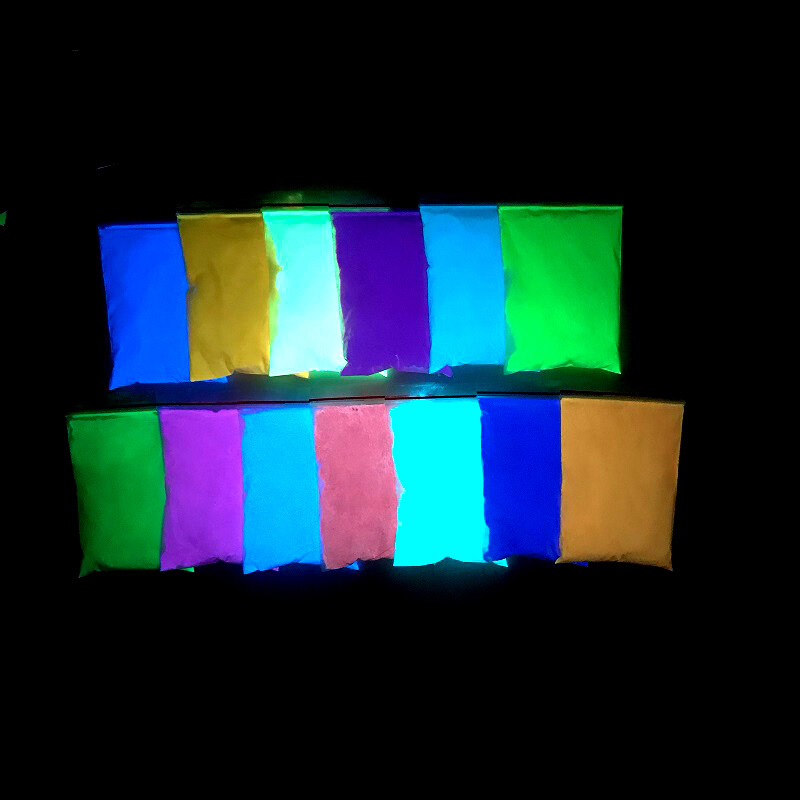

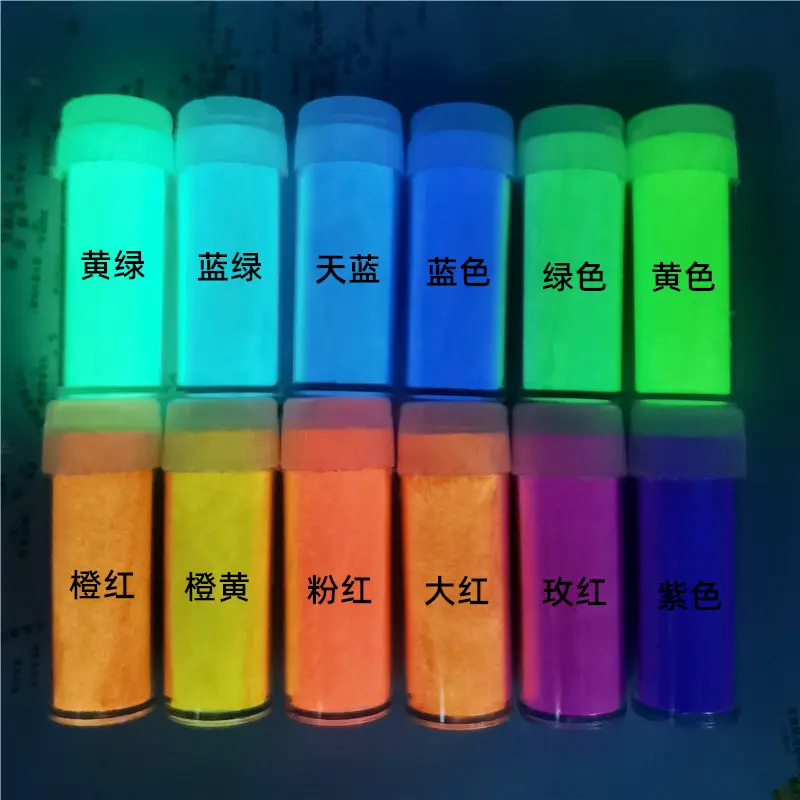

Even we see the photoluminescent pigment appearance is yellow powder,but after they absorb the light in the day,they will glow different color lights.Used for PVC or coating or other plastics products,yellow green color is most popular.

Currently some sport shoes manufacturer also used photolumisnescent pigment for EVA shoes.To make the shoes special to attract children's eyes.

What's the application of photoluminescent pigment powder?

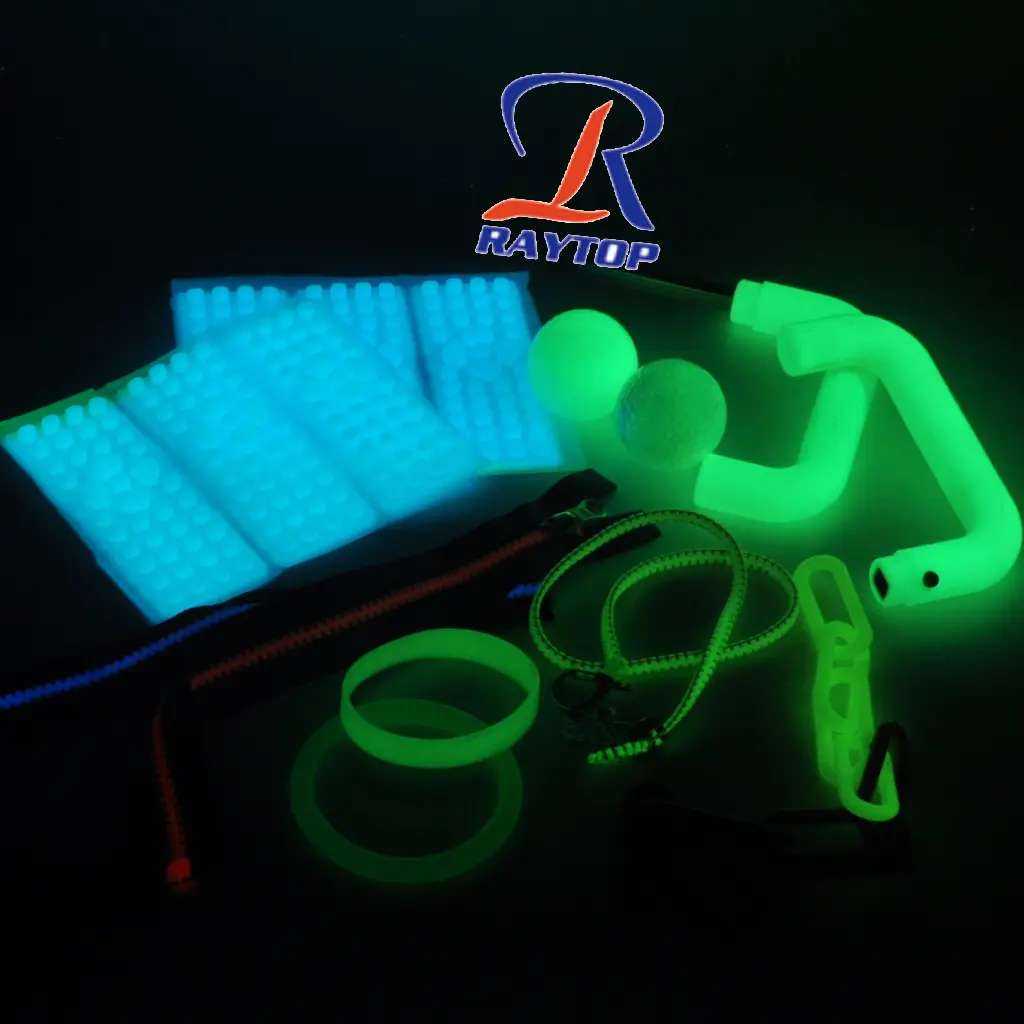

It can be made into various photoluminescent products, and have been widely applied to fire prevention, place-name signs, household electric appliances, clocks and watches, finery, garments, craftworks and gifts, and so on.

Technical Data of photoluminescent pigment

Other name:Glow In The Dark Pigment

Material:strontium aluminate

Appereance:yellowish powder

CAS No.:12004-37-4

EINECS No.:234-455-3

Usage:Ceramic Pigments, Coating Pigment, Cosmetic Pigment, Ink Pigments, Plastic & Rubber Pigment, Spray painting pigment;brushing

Other name:Glow In The Dark Pigment

Color in dark:yellow-green, blue-green, purple, skye-blue,etc

Application:coating pigment; ink pigment;

Partice size:5-15um,25-35um,45-55um,65-85um,etc.

Feature:glow in dark after absorbing light

What are the characteristics of the structure of photoluminescent polymers?

The characteristic is that it cannot be crystallized. The three-dimensional configuration of the photoluminescent polymer powder molecules will affect the performance of the material. The isotactic polystyrene has a relatively regular structure, can be crystallized, and has a melting point of 240 °C. The atactic polystyrene has an irregular structure, cannot crystallize, and has a softening temperature of 80 °C.

The whole process of solid photoluminescence

It is divided into the following three steps:

① Photoluminescence absorption. There are roughly three types: the first is matrix absorption, which excites electrons from the valence band to the conduction band. In the second category, it sends electrons in the localized state to the conduction band or excites electrons in the valence band to the localized state. The third type is limited to the absorption inside the separation center.

② Energy adjustment. After internal adjustment, part of the energy is surrendered to reach the luminous state.

③ The transition from the luminescent state to the ground state emits light. The photoluminescence of insulators is mostly the luminescence of discrete centers. It requires that the donor's luminescence spectrum and the acceptor's absorption spectrum overlap, and the distance between the two must be near the critical distance. The luminescence process may also be accompanied by quenching process, so that the energy is consumed as heat energy. For semiconductors, it is mainly compound luminescence. In semiconductors, electrons are easy to move, and its recurrent light is through the movement of carriers. There can also be discrete light-emitting centers, and the whole process of light-emitting is carried out in the center. This can also be caused by electrons and holes moving to the center to emit the characteristic spectrum of the center. Compound luminescence should meet two conditions, which are energy conservation and momentum conservation, which is difficult to meet. However, when electron and hole pairs meet, they form a combination called excitons due to the Coulomb gravity between them. It has no charge, can diffuse in the crystal, and can also be bound near an impurity. In the non selective excitation, the excitation density of the matrix is higher than that of the luminescence center. The trend of cathodoluminescence is similar to that when the matrix is excited. It should be that the electron hole pairs produced by high-energy electrons entering the luminescent body recombine at the luminescent center. In low dimensional materials such as quantum wells and superlattices, the energy bands are replaced by excitons, which can change the properties of luminescence.

Applications of Photoluminescent Pigments powder

The most common application of photoluminescent pigments powder is in fluorescent lamps. It is the ultraviolet light generated by the gas discharge in the lamp tube that excites the luminescent powder on the tube wall to emit visible light. Its efficiency is about 5 times that of incandescent lamps. In addition, the photoluminescence of "black light" and other monochromatic lamps is widely used in printing, reproduction, medical treatment, plant growth, insect trapping and decoration. Upconversion materials can convert infrared light into visible light, which can be used to detect infrared light, such as the light field of infrared lasers.

Photoluminescent pigments powder can provide information about the structure, composition, and atomic arrangement of the material, and are a non-destructive and highly sensitive analytical method. The application of laser makes this kind of analysis method go deep into the fields of micro area, selective excitation and transient process, making it further become an important research method, applied to the fields of physics, material science, chemistry and molecular biology, etc. New frontier disciplines emerge.

Photoluminescent materials powder used in clothing

The clothes worn by road signs and road maintenance workers and the clothes worn by police are all reflective materials. Some are luminous bodies made of photoluminescent luminous powder materials. Or use a small light source to make hollow objects with luminous powder. Sufficient light body display.

What are the ingredients of Photoluminescent Pigments powder

If the photoluminescent Pigments powder is natural, the main ingredient is CaF2, but it also contains a small amount of other impurity ions (complex composition), which leads to luminous;

If it is artificially synthesized, it is mainly SrAl2O4:Eu (green light) at present, although other types are also available, but they are not popular.

How to use Photoluminescent Pigments powder?

In the application of various handicraft industries and toy industries, first add the diffusion oil to the raw materials and stir for one minute, then add the Photoluminescent Pigments powder and stir for one minute, and then add the color powder and stir for two minutes. The stirring time should not be too long.

When Photoluminescent Pigments powder is used for printing, high-viscosity resin can be used, and anti-settling agent can be added. It needs to be stirred evenly before use. Diluent can be used to adjust the viscosity, which can improve the brightness and luminous time of the printed pattern.

When Photoluminescent Pigments powder is used in coatings, the selected resin should have good light transmittance. At the same time, since Photoluminescent Pigments powder is a weakly alkaline substance, the resin should preferably be neutral or weakly alkaline. To manufacture water-based paints, luminescent pigments require surface water-resistant treatment.

Precautions for use with Photoluminescent Pigments powder:

1. Photoluminescent Pigments powder should be avoided in acidic environment. Because Al2O3 reacts with acid.

2. Photoluminescent Pigments powder should avoid contact with water and keep it sealed as much as possible. Because it will absorb moisture in the air if it comes in contact with water, making the luminous powder black and not glowing and agglomerating.

3. Photoluminescent Pigments powder should avoid contact with metal, which will affect the unsaturated state of the luminescent powder and affect the luminescence.

4. Photoluminescent Pigments powder should avoid high temperature and high speed friction, which will change the existing structure of luminescent powder.

5. The radioactive luminous powder is mixed with radioactive substances in Photoluminescent Pigments powder, and the ray continuously emitted by the radioactive substances is used to excite the fluorescent powder to emit light. lead to a small scope of application