What is the Luminous powder?

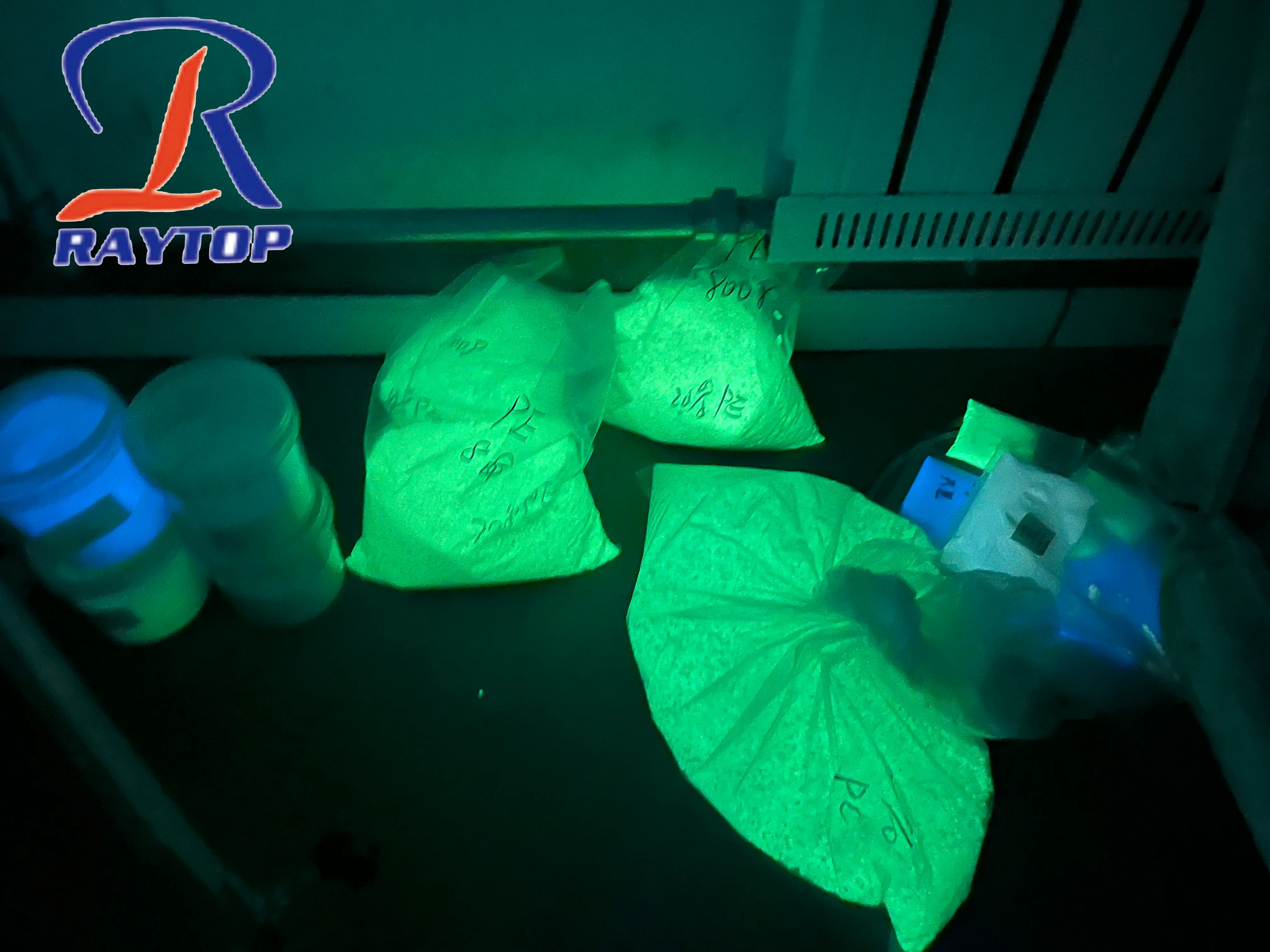

Luminous powder, also known as fluorescent powder, phosphorescent powder, or fluorescent pigment, is a type of powder material that can emit light in the dark,so we also named it glow in the dark powder.Its luminescent properties are generated through the excitation of phosphorescent substances within the powder.

Luminous powder primarily contains phosphorescent materials that absorb energy when exposed to light and slowly release this energy in the absence of light, emitting visible fluorescence. This process is known as fluorescence emission. Typically, luminous powder absorbs light energy under ultraviolet light (such as sunlight or artificial UV light) and continues to glow in the dark.

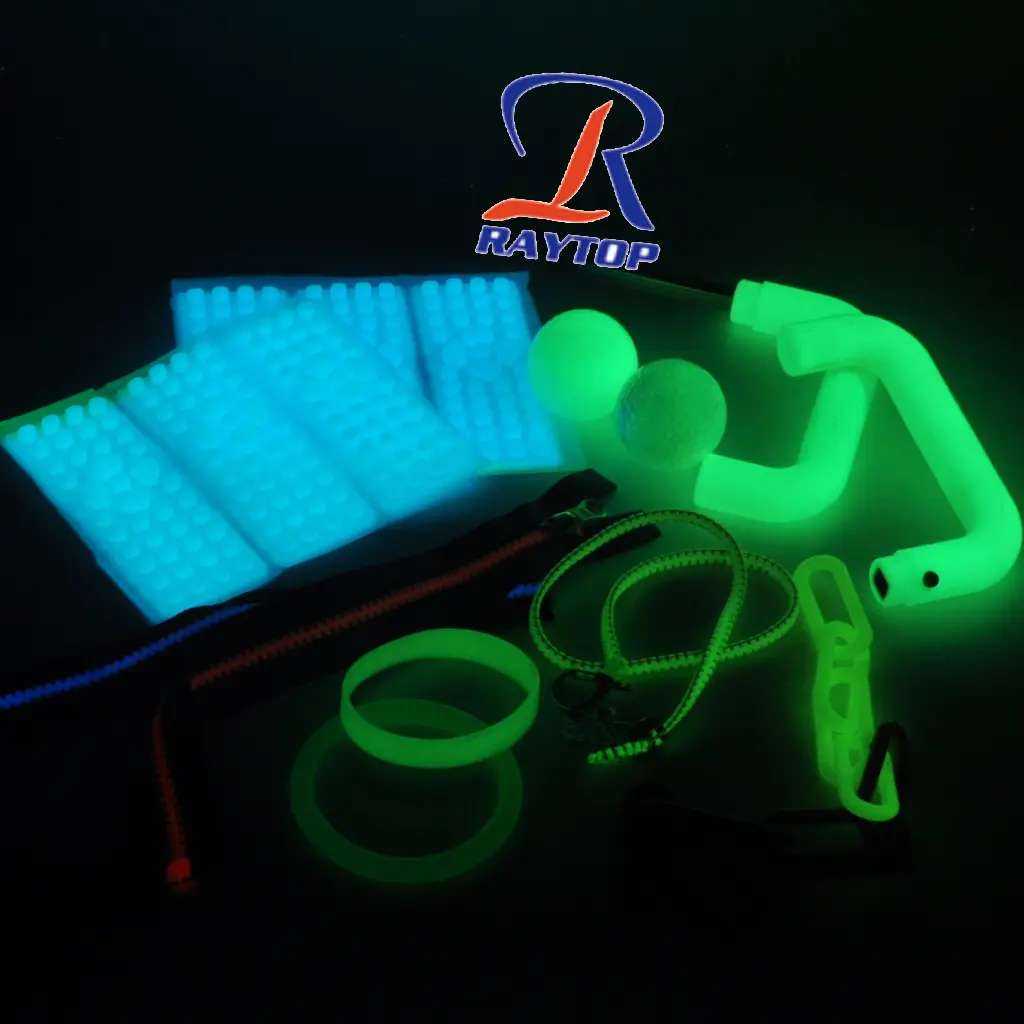

Luminous powder finds widespread use in the production of glow-in-the-dark paint, fluorescent inks, luminous coatings, and various other fluorescent products. These products absorb light during the day and emit a bright glow during the night or in dark environments. Applications of luminous powder include artistic creations, decorations, safety signage, adding a unique and captivating effect to a variety of creative and practical projects.

How to make paint glow in the dark?

Creating glow-in-the-dark paint can add an exciting and whimsical touch to various projects. Whether you want to enhance your artwork, revamp your living space, or engage in a fun DIY activity, making glow-in-the-dark paint is both easy and enjoyable.

Manufacturing Glow-in-the-Dark Paint: Technical Process

Raw Materials:

Glow Pigments: Utilize high-quality phosphorescent or fluorescent pigments, such as strontium aluminate or zinc sulfide, known for extended afterglow.

Clear Binder/Base: Choose a clear, stable, and durable paint binder suitable for the intended application, like acrylic, epoxy, or polyurethane.

Stabilizers and Additives: Incorporate additives for stability, adhesion, and rheological control, ensuring optimal performance and shelf life.

Production Steps:

Quantifying Ingredients:

Determine the required quantity based on the desired production volume, considering the pigment-to-binder ratio and application thickness.

Mixing Ratios:

Establish a precise mixing ratio, often ranging from 15-50% glow pigment to the clear binder, depending on the desired glow intensity. Experiment to achieve optimal luminescence without compromising the paint's structural integrity.

Mixing Process:

Employ high-speed dispersers or mixers to ensure thorough dispersion of the glow pigments within the clear binder. Homogeneity is critical to achieving consistent glow performance.

Quality Control:

Implement quality control measures such as rheological testing, particle size analysis, and luminance measurements to guarantee the paint meets desired specifications.

Viscosity Adjustment:

Adjust the viscosity of the paint to accommodate specific application methods, ensuring a smooth and even coat. This may involve the incorporation of rheology modifiers.

Packaging:

Fill the produced glow-in-the-dark paint into suitable packaging, accounting for factors like storage stability and ease of application.

Usage Instructions for Customers:

Surface Preparation:

Ensure the application surface is clean, dry, and free from contaminants that may hinder adhesion.

Application Techniques:

Recommend suitable application methods based on the paint type (acrylic, epoxy, etc.), including brushing, spraying, or rolling.

Coverage Rates:

Provide guidance on the required coverage rate, typically expressed in square meters per liter, to achieve the desired glow effect.

Charging Duration:

Advise users on the optimal charging duration, typically through exposure to natural or artificial light, to maximize the afterglow intensity and duration.

Key Metrics:

Afterglow Duration:

Measure the afterglow duration, expressed in minutes or hours, to quantify the sustained luminescence of the paint.

Luminance Levels:

Conduct luminance tests to establish the initial and sustained brightness levels, measured in mcd/m² (millicandelas per square meter).

Application Yield:

Calculate the coverage area per unit of paint (square meters per liter or gallon) to guide customers on product quantity required for specific projects.

In conclusion, the production of glow-in-the-dark paint at a factory level involves precise formulations, quality control measures, and clear guidance for end-users. The success of the product hinges on the selection of high-quality raw materials and meticulous manufacturing processes.

Below are 5 methods to make paint glow in the dark

1. Incorporate High-Quality Glow Pigments

Enhance your paint's glow by incorporating premium phosphorescent or fluorescent pigments. Opt for renowned suppliers offering vivid and long-lasting pigments for optimal luminosity.

Example: Elevate your paint's glow with top-tier phosphorescent pigments that guarantee a mesmerizing and enduring luminescent effect.

2. Experiment with Mixing Ratios for Intensity

Achieve the desired glow intensity by experimenting with different ratios of glow pigments to clear paint medium. Find the perfect balance for a vibrant and sustained glow.

Example: Fine-tune your paint's glow by adjusting the ratio of phosphorescent pigments to clear paint, creating a customized luminous masterpiece.

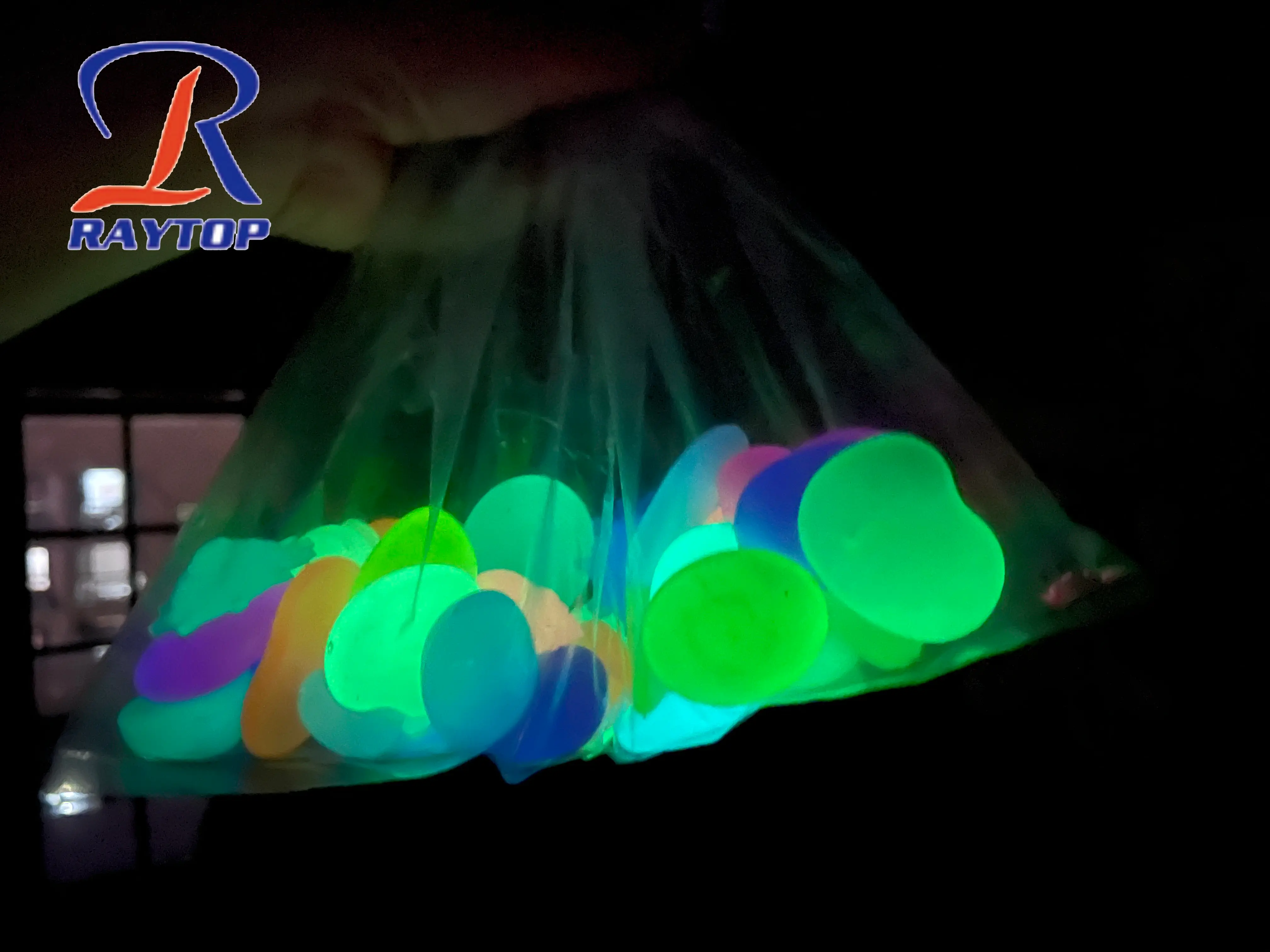

3. Explore Multi-Color Combinations

Unleash creativity by blending different colors of glow pigments to create a diverse palette. Experiment with combinations that suit your artistic vision, providing a unique and captivating glow.

Example: Transform your art with multi-color glow effects by blending various phosphorescent pigments, adding depth and intrigue to your creations.

4. Choose UV-Resistant Clear Paint Medium

Ensure longevity by opting for a clear paint medium with UV-resistant properties. This protects the glow-in-the-dark effect from environmental factors, ensuring sustained luminosity over time.

Example: Preserve your paint's brilliance with a UV-resistant clear medium, safeguarding against environmental influences and ensuring a lasting, radiant glow.

5. Provide Clear Instructions for Charging

Empower users with clear instructions on how to charge the glow-in-the-dark paint effectively. Guide them on optimal light exposure durations to maximize luminosity.

Example: Unlock the full potential of your paint's glow by following our simple charging instructions, ensuring a vivid and enduring luminescent display.

The above 5 methods are common ways to make paint glow in the dark. Here are some tips. If you want to make paint glow in the dark yourself, please consult our experts to give you the most accurate and personalized answer.

Pros and Cons

Pro

Aesthetic Appeal:

Glow-in-the-dark paint adds a unique and visually striking element to surfaces, making them stand out in low-light conditions.

Safety Enhancement:

Applications in safety signage or emergency exits can improve visibility and aid in navigation during power outages or low-light situations.

Decorative Options:

Provides a creative and customizable option for artists, designers, and DIY enthusiasts to enhance their projects with luminescent features.

Novelty and Entertainment:

Ideal for creating captivating and novel visual effects in entertainment venues, theaters, and themed environments.

Versatility:

Applicable to various surfaces, including walls, artwork, fabrics, and objects, allowing for diverse creative applications.

Cons

Limited Duration:

Glow-in-the-dark effects are typically temporary and diminish over time, requiring periodic recharging.

Charging Requirement:

The glow effect relies on exposure to light, necessitating adequate charging for optimal luminosity, which may not be suitable for all environments.

Initial Cost:

Quality glow pigments can be relatively expensive compared to traditional paint, increasing the initial cost of the project.

Color Limitations:

Glow pigments may limit color options, as they are often available in shades of green or blue, potentially restricting design choices.

Application Challenges:

Achieving a consistent and even application can be challenging, requiring careful mixing and application techniques.

Environmental Impact:

Some glow pigments may contain rare or heavy metals, posing environmental concerns during production and disposal.

Sensitivity to Environmental Factors:

The glow effect may be influenced by external factors such as temperature, humidity, and the presence of ambient light.

Longevity Issues:

The glow intensity may diminish gradually over time, and the paint may require recoating for sustained effects.

While glow-in-the-dark paint offers unique and visually appealing features, it comes with considerations such as temporary effects, charging requirements, and initial costs. The decision to use such paint should be based on the specific requirements and constraints of the project or application.

Applications of Glow-in-the-Dark Paint in the Dark

Safety Signage

Glow-in-the-dark paint is widely used for creating safety signage in buildings, industrial facilities, and public spaces. Emergency exit signs and directional indicators become highly visible in the dark, aiding in evacuation procedures during power outages.

Decorative Artwork

Artists and designers often use glow-in-the-dark paint to create unique and visually stunning artwork. The luminescent effect adds an extra dimension to paintings, murals, and sculptures, especially in spaces with low ambient lighting.

Nighttime Navigation

Outdoor pathways, steps, and walkways can be enhanced with glow-in-the-dark paint to improve visibility at night. This is particularly useful in gardens, parks, and recreational areas.

DIY Projects

DIY enthusiasts use glow-in-the-dark paint for various projects, such as creating custom home decor items, furniture accents, and craft projects. It provides a novel and creative element to handmade items.

Entertainment and Events

Glow-in-the-dark paint is popular in entertainment venues, theaters, and theme parks for creating immersive and visually captivating environments. It adds an element of surprise and excitement to performances, exhibitions, and events.

Children's Rooms and Play Areas

Glow-in-the-dark paint is often used to create fun and whimsical designs in children's rooms. It can be applied to walls, ceilings, or furniture to create a magical and interactive space.

Novelty Items

Various consumer products, such as clothing, accessories, and toys, incorporate glow-in-the-dark elements for novelty and aesthetic purposes.

Science and Educational Displays

In educational settings, glow-in-the-dark paint is employed for interactive displays and exhibits. It can highlight specific information or elements in a darkened environment, enhancing the learning experience.

Special Effects in Film and Theater

The film and theater industries use glow-in-the-dark paint for special effects, creating surreal scenes or enhancing costumes that need to stand out in low-light conditions.

Party and Event Decor

Glow-in-the-dark paint is used to create unique party decor elements, such as glowing murals, table centerpieces, and themed decorations for nighttime events.

Promotional and Branding Materials

Businesses may use glow-in-the-dark paint in promotional materials, signage, or branding elements to create memorable and attention-grabbing displays.

Customized Automotive Accents

Some automotive enthusiasts use glow-in-the-dark paint for customizing car interiors or exterior accents, providing a distinctive look, especially during nighttime driving.

In conclusion, the versatility of glow-in-the-dark paint makes it applicable across various industries and creative endeavors, enhancing both practical and aesthetic aspects in dark or low-light environments.

How to pack?

Ensuring the proper packaging of glow-in-the-dark paint is crucial to maintaining its quality and effectiveness. Here are guidelines for packaging glow-in-the-dark paint, especially for low-light conditions:

Light-Blocking Containers:

Utilize light-blocking containers made of opaque materials to shield the paint from ambient light. Dark-colored plastics or metal containers with light-tight seals are ideal for preserving the glow-in-the-dark properties.

Sealed Packaging:

Ensure that the packaging is tightly sealed to prevent exposure to external light and environmental contaminants. Use seals, lids, or caps that securely lock in place to maintain the paint's integrity.

Opaque Labels:

Apply labels using opaque materials that do not allow light to penetrate. Clearly indicate product details, instructions, and safety information on the labels without compromising the light-blocking properties of the packaging.

UV-Resistant Materials:

If possible, choose packaging materials with UV-resistant properties to provide an additional layer of protection against potential light exposure during storage and transportation.

Indoor Storage Recommendations:

Advise customers to store the glow-in-the-dark paint indoors in a cool, dark place when not in use. This helps to prevent unintended charging and degradation of the glow effect due to prolonged exposure to light.

Protective Outer Packaging:

Consider providing additional outer packaging, such as a box or carton, to shield the light-blocking containers from direct light during transit and storage.

Instructional Inserts:

Include clear instructions on how to store the glow-in-the-dark paint to maintain its glow properties. Provide information on avoiding prolonged exposure to light and the importance of keeping the packaging sealed.

Quality Assurance Measures:

Implement quality assurance measures during the packaging process to confirm the integrity of each container. This may include visual inspections, light exposure tests, or other relevant checks.

Tamper-Evident Features:

Integrate tamper-evident features into the packaging to assure customers that the product has not been opened or compromised before purchase.

Recharge Instructions:

Include concise instructions on how customers can recharge the glow-in-the-dark paint effectively. Highlight the recommended light sources and durations for optimal results.

Environmentally Friendly Packaging:

Consider using eco-friendly packaging materials to align with sustainability goals. However, prioritize the light-blocking properties to ensure the product's efficacy.

By implementing these packaging strategies, manufacturers can help preserve the glow-in-the-dark properties of the paint and ensure that customers receive a product that meets their expectations for luminosity and longevity.

RFQ:

Q:How much dosage need to add glow in the dark powder into painting?

A:The recommended ratio for adding phosphorescent powder to paint is between 30% and 50%. The specific ratio can be adjusted based on the customer's brightness requirements for the phosphorescent powder. Generally, a higher proportion of powder results in greater brightness, provided it remains within reasonable limits.

Q1: What materials do I need to make glow-in-the-dark paint?

A: You'll need glow pigments (phosphorescent or fluorescent), a clear paint medium (acrylic, epoxy, etc.), and additional materials like stirrers, brushes, and mixing containers.

Q2: Can I use any type of paint for making glow-in-the-dark paint?

A: Ideally, choose a clear paint medium compatible with your chosen glow pigment. Acrylic, epoxy, or polyurethane paints are commonly used.

Q3: How do I mix glow pigments with the paint medium?

A: Gradually add glow pigments to the clear paint medium, following a recommended mixing ratio (usually around 15-50% pigment to paint). Stir thoroughly to ensure an even distribution.

Q4: What are the best ratios for mixing glow pigments with paint?

A: Ratios depend on the desired glow intensity. Start with a lower ratio and adjust based on experimentation. A common starting point is around 1 part glow pigment to 5 parts paint.

Q5: Can I use multiple colors of glow pigments in one paint mixture?

A: Yes, you can mix different colors of glow pigments to create custom colors. Experiment to achieve the desired hue and glow effect.

Q6: How long does the glow last?

A: The glow duration varies based on the quality of the glow pigments. High-quality pigments can provide a sustained glow for several hours.

Q7: How do I charge the glow-in-the-dark paint?

A: Expose the painted surface to natural or artificial light for an adequate duration. The longer the exposure, the brighter and longer the glow.

Q8: Can I use glow-in-the-dark paint outdoors?

A: Yes, you can use glow-in-the-dark paint outdoors. However, protect the painted surface from harsh weather conditions to ensure longevity.

Q9: Does temperature affect the glow-in-the-dark effect?

A: Extreme temperatures may impact the glow-in-the-dark effect. Optimal performance is typically achieved within a moderate temperature range.

Q10: Can I apply glow-in-the-dark paint to any surface?

A: While versatile, consider the material and surface characteristics. Ensure a clean, dry surface for proper adhesion.

Q11: Can I mix glow-in-the-dark paint with regular paint?

A: Yes, you can mix glow-in-the-dark paint with regular paint to create unique effects. Experiment with ratios to achieve the desired glow intensity.

Q12: How do I ensure an even application of glow-in-the-dark paint?

A: Use appropriate brushes or application tools. Apply thin, even coats to prevent clumping and ensure a consistent glow.

Q13: Is glow-in-the-dark paint safe?

A: Most commercially available glow pigments are non-toxic. However, always check the product specifications and follow safety guidelines during use.

Q14: Can I seal or varnish over glow-in-the-dark paint?

A: Yes, you can seal or varnish over glow-in-the-dark paint to protect the surface. Ensure the sealant is compatible with the paint medium.

Q15: How do I clean surfaces painted with glow-in-the-dark paint?

A: Clean painted surfaces using a mild detergent and water. Avoid abrasive cleaners to prevent damage to the glow-in-the-dark effect.