Brighteners are widely used in the production of textiles, papermaking, washing powder, soap, rubber, plastics, pigments and paints. Brighteners, also called optical brighteners and fluorescent brighteners, are organic compounds that can improve the whiteness of fiber fabrics and paper.

Many friends may have seen the three words brightener in their lives, but it is not too clear what the whitening agent is for. Let's take a look together below.

Technical Specifications

| Parameter | Specification | Notes |

|---|---|---|

| Product Name | Universal Optical Brightener OB-202 | Customizable: heat-resistant (OB-202H), eco-friendly (OB-202E) |

| Chemical Type | Stilbene-4,4'-disulfonic acid derivative | High fluorescence quantum yield (≥0.9) |

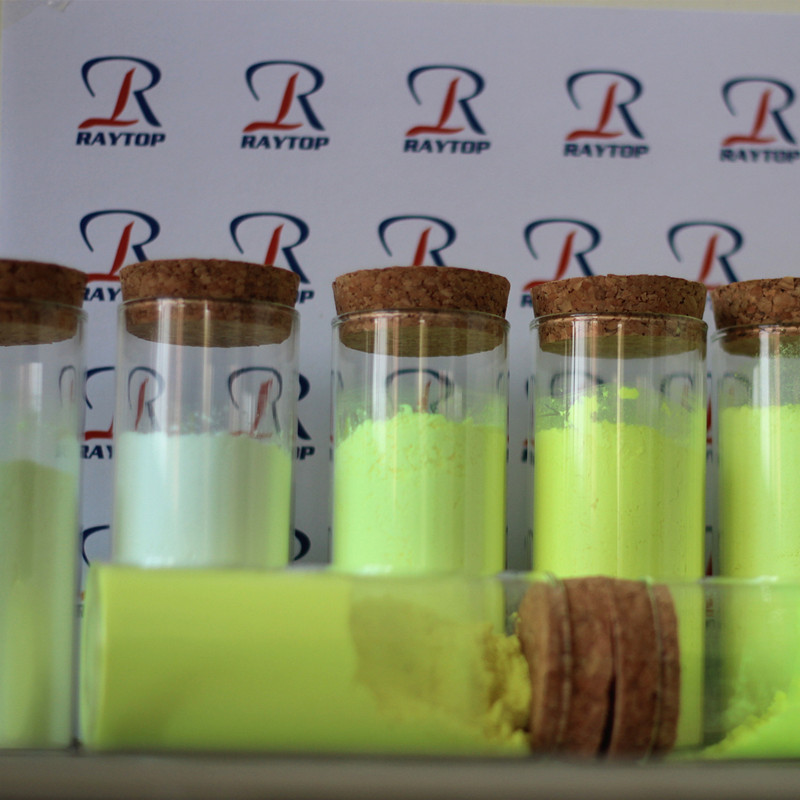

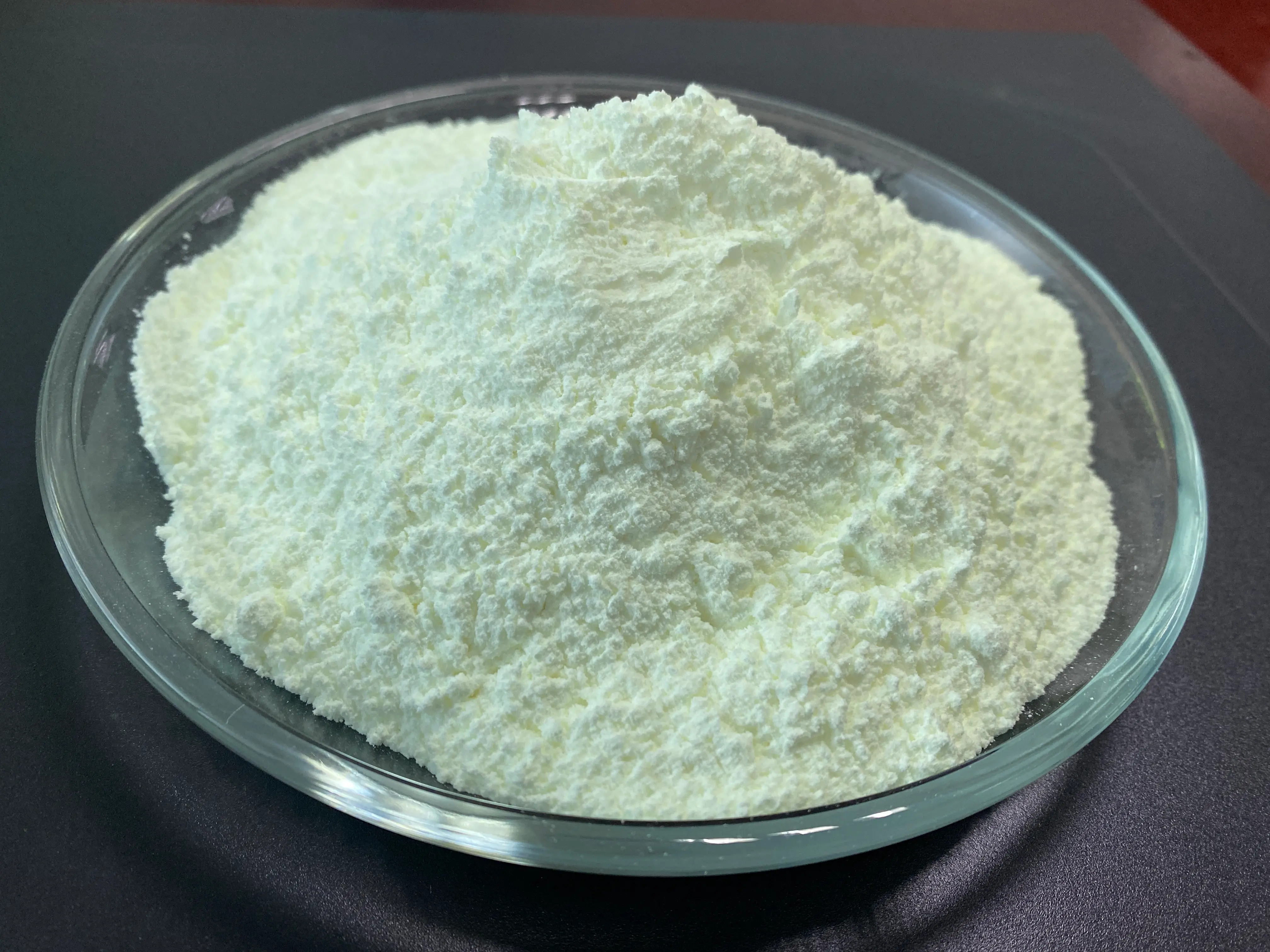

| Appearance | Pale yellow to white powder | Free of visible impurities |

| Purity (HPLC) | ≥98% | Heavy metals (Pb/Cd) ≤10ppm |

| Moisture Content | ≤0.5% | Meets moisture resistance requirements for plastics/detergents |

| Solubility | Easily soluble in warm water (50°C), ethanol | Insoluble in alkanes |

| Applicable Temperature Range | Ambient to 220°C (plastics processing) | Heat-resistant OB-202H withstands up to 280°C |

Price Reference (USD/kg)

| Product Model | Packaging | Base Price (USD/kg) | Notes |

|---|---|---|---|

| OB-202 (Universal) | 25kg/carton drum | 8.5−10.5 | Standard industrial grade, suitable for plastics/detergents |

| OB-202H (Heat-Resistant) | 25kg/carton drum | 12.0−14.0 | For high-temperature processing (e.g., engineering plastics) |

| OB-202E (Eco-Friendly) | 25kg/carton drum | 15.0−17.0 | APEO-free, low VOC, suitable for food packaging |

Recommended Dosage Guidelines (Based on Total Formulation)

| Application Field | Recommended Dosage | Effect Description |

|---|---|---|

| Plastics (PE/PP) | 0.05%-0.2% | Every 0.05% dosage increase raises whiteness (ISO) by 1-2 |

| Detergents (Liquid) | 0.1%-0.5% | Post-wash fabric whiteness increases by 15-30% (vs. blank sample) |

| Textiles (Dyeing) | 0.5%-2% (after-treatment agent) | Light-colored fabrics: whiteness increases by 20-40%; dark-colored fabrics: vibrancy increases by 10-15% |

| Paper (Coating) | 0.2%-1% (coating formulation) | Whiteness (ISO) increases by 15-30%; ink coverage increases by 0.05-0.1 |

Support & Services

Sample Testing: Free small-batch samples (500g) provided for whiteness, compatibility, and other tests.

Technical Guidance: Formulation optimization advice for each industry (e.g., temperature matching for plastic processing, compatibility debugging for detergents).

Custom Production: Adjustable purity, particle size, heat resistance, etc., available (minimum order: 1 ton).

Global Logistics: Partnered with DHL, Maersk, etc., supporting sea/air freight and customs clearance assistance (CO, MSDS provided).

Use of brighteners

Brighteners are widely used in papermaking, textiles, washing powder and soap industries; brighteners are derivatives of phenylpyrazoline, mainly used in the production of acrylic fiber spinning, textiles and plastic products; 4-A Base-7-dimethylamine coumarin whitening agent is used in products such as wool fabrics, nylon fabrics, soaps and detergents.

1. Plastics Processing: Elevating Aesthetics and Quality

Advantages:

Neutralizes yellowing caused by aging, recycled materials, or fillers (e.g., calcium carbonate) in plastics, significantly improving whiteness (ΔE*ab can increase by 2-5).

Enhances surface gloss (gloss increases by 10-20%), improving the premium feel of products.

Compatible with most thermoplastics (PE, PP, ABS, PC, PET, etc.), with no blooming or impact on mechanical properties.

Compliant with food contact safety standards (e.g., FDA 21 CFR 178.3297), suitable for food packaging plastics.

2. Detergents: Keeping Fabrics "Whiter Than New"

Advantages:

Targets cotton, polyester, blends, and other fabrics, neutralizing post-wash yellowing through fluorescence compensation, increasing whiteness by 15-30%.

Enhances color vibrancy of colored garments (color saturation increases by 10-15%), restoring "factory-fresh" color.

Low-foaming and easy to rinse, compatible with surfactants, enzymes, and other detergent ingredients without compromising cleaning performance.

Eco-friendly formulation (APEO-free, low COD), meeting EU Ecolabel and U.S. EPA green chemistry standards.

3. Textiles: Boosting Fiber Luster and Color Fastness

Advantages:

Penetrates fibers to distribute fluorescent groups uniformly, increasing fabric whiteness (ISO 105-B02 standard) by 20-40%.

Synergizes with dyes to deepen color intensity (especially for light shades), reducing dye usage by 10-15%.

Enhances fiber resistance to photo-aging (UV absorption rate ≥80%), extending fabric lifespan.

Compatible with reactive dyes, disperse dyes, and other processes without affecting color fastness (wash fastness ≥4 grade).

4. Paper Production: Creating a "Snow-White" Printing Base

Advantages:

Neutralizes yellowing from lignin residues in wood pulp or recycled paper pulp, increasing paper whiteness (ISO 11475) by 15-30%.

Improves paper gloss (smoothness increases by 10-15%), enhancing ink adhesion (ink coverage increases by 5-8%).

Synergizes with strength additives (e.g., cationic starch) and fillers (e.g., titanium dioxide), reducing overall costs.

Compliant with food packaging paper safety standards (e.g., GB 4806.8-2016), free from migration risks.

Introduction to brighteners

Brighteners, also called optical brighteners and fluorescent brighteners, are organic compounds that can improve the whiteness of fiber fabrics and paper. Brighteners can be classified according to their chemical structure and use. According to the chemical structure, they can be divided into five types: stilbene type, coumarin type, pyrazoline type, benzoxazide type, and phthalimide type; According to the application, it can be divided into fluorescent whitening agent for detergents, fluorescent whitening agent for textiles, fluorescent whitening agent for papermaking, fluorescent whitening agent for plastics and synthetic materials, and fluorescent whitening agent for other purposes.

The main function of the brightener is to convert the invisible ultraviolet radiation absorbed by the product into purple-blue fluorescent radiation, which complements the original yellow radiation to become white light, and improves the whiteness of the product under sunlight.