Deodorizer Introduction:

Introduction to deodorant:

In modern life, plastic products are widely used in various fields. However, some plastic products may emit an unpleasant smell, which may cause inconvenience to users. In order to solve this problem, many manufacturers have adopted deodorants, which use the principles of adsorption and encapsulation to inject fresh smells into plastic products and improve user comfort. This article will explore how deodorant works and the benefits it brings.

How it works: Adsorption and Encapsulation Deodorants work mainly through adsorption and encapsulation. When plastic products emit pungent odors, the active ingredients in deodorants absorb and neutralize these odor molecules, reducing their concentration in the air. In addition, deodorants can encapsulate volatile substances, preventing them from diffusing into the surrounding environment and further reducing the spread of bad odors.

We produce this deodorant for use in plastic processing. Plastic factories need this deodorant in the process of producing plastic products to solve the problem of bad odor in plastics.

Deodorants: Bringing Freshness to Plastics

How it works: Adsorption and Encapsulation Deodorants work mainly through adsorption and encapsulation. When plastic products emit pungent odors, the active ingredients in deodorants absorb and neutralize these odor molecules, reducing their concentration in the air. In addition, deodorants can encapsulate volatile substances, preventing them from diffusing into the surrounding environment and further reducing the spread of bad odors.

What's the Benefits when use deodorizer during the manufacturing:

Enhanced Product Quality and Image: The odor of plastic products is one of the most direct factors influencing user experience. By utilizing deodorizers, manufacturers can effectively eliminate offensive odors, improving product quality and image. This enhances user satisfaction and elevates brand reputation.

Improved User Experience: The use of deodorizers can provide consumers with a better user experience. Pungent odors often cause discomfort and annoyance, but deodorizers effectively mask or neutralize these odors, creating a fresh and pleasant environment for users.

Diverse Choices: Deodorizers come in a variety of fragrance options. Manufacturers can select suitable deodorizer scents based on different products and consumer preferences. This provides consumers with more personalized choices, allowing them to obtain products that cater to their individual preferences.

Environmental and Health Benefits: Most deodorizers employ environmentally friendly and health-conscious formulations, free from harmful substances that pose no risk to human health or the environment. This means that plastic products using deodorizers meet health and environmental standards, fulfilling the requirements for sustainable development.

Such a deodorant makes the plastic products you produce have no bad smell, and doubles your profit.

Technical Specifications of Deodorizers:

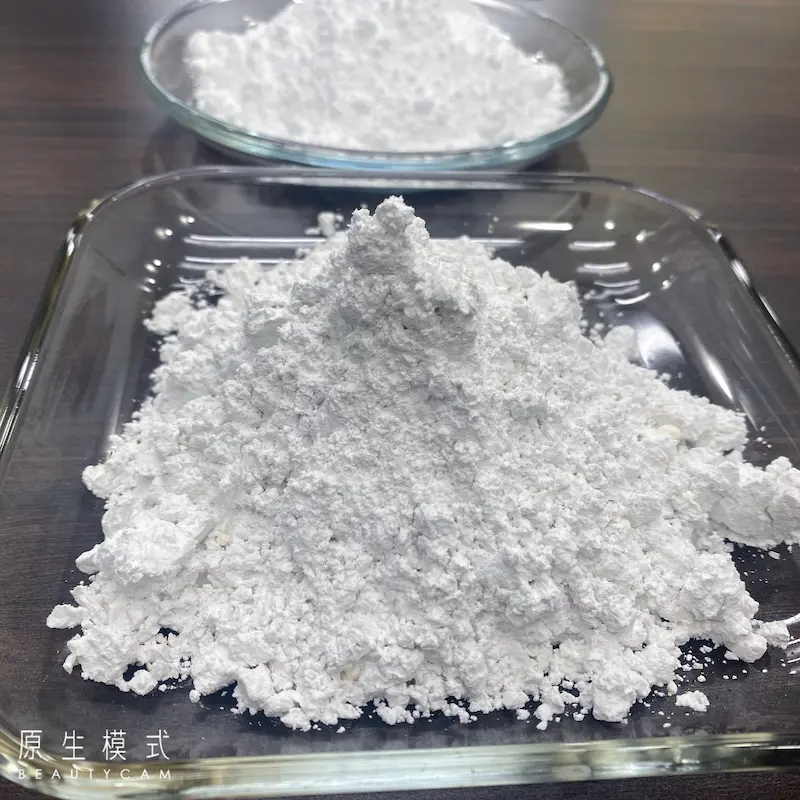

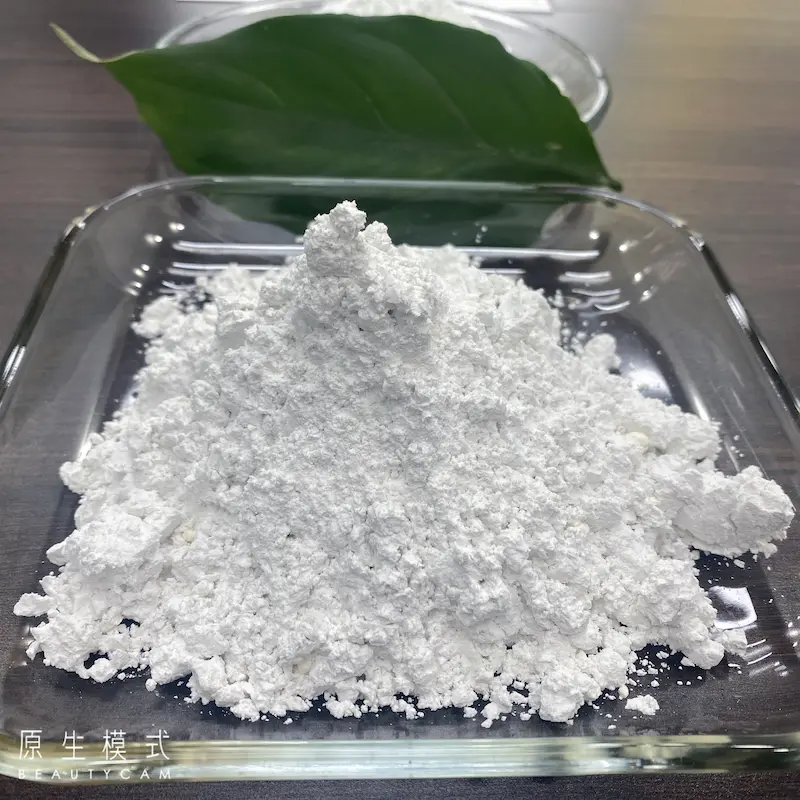

Appearance: For example, colorless crystals, transparent liquid, or solid particles.

Density: Typically ranging from 0.5 to 1.5 g/cm³.

Melting and boiling points: The melting point may vary between 50-200°C, while the boiling point depends on the nature of the deodorizer.

Solubility: Describing the degree of solubility in specific solvents, such as soluble in water, organic solvents, or oils.

pH value: Usually categorized as acidic (pH < 7), neutral (pH = 7), or alkaline (pH > 7).

Particle size distribution: Described by parameters like average particle size, maximum particle size, or particle size distribution curve, for example, an average particle size of 10-100 micrometers.

Specific surface area: Typically ranging from 1 to 500 m²/g, reflecting the active surface area of the deodorizer particles.

Volatility: Depending on the application requirements, deodorizers can exhibit different volatility characteristics, ranging from very low volatility to high volatility.

Flash point: The lowest temperature at which the deodorizer can ignite under specific conditions, which can range between 50-300°C.

If you use our above specification plastic deodorant, the effect is remarkable.

How to use Deodorizer:

During the production process, the deodorizer can be used to eliminate unpleasant odors or malodors from the product. Here are general instructions on how to use a deodorizer:

Identify the target product or material for deodorization: Determine the specific product or material that requires deodorization, such as plastic products, textiles, coatings, etc.

Select an appropriate deodorizer: Choose a suitable deodorizer based on the characteristics of the product or material and the deodorization requirements. Consider factors such as the composition of the deodorizer, the deodorizing mechanism, and its impact on product performance.

Pre-treatment: Before the production process begins, pre-treatment can be carried out on raw materials or intermediate products. Add an appropriate amount of deodorizer to the raw materials and stir, mix, or spray it to ensure uniform distribution and sufficient contact of the deodorizer with the parts that need odor removal.

Addition during the production process: Add the deodorizer in the required amount according to the production process and needs. It can be added through direct mixing, dissolution, coating, or spraying.

Mixing and stirring: Ensure thorough mixing and stirring of the deodorizer with the product to facilitate its effectiveness.

Reaction or adsorption time: In some cases, the deodorizer may require a certain amount of time to react or adsorb odorous substances. Allocate sufficient time during the production process for the deodorizer to achieve optimal results.

Testing and evaluation: Conduct necessary testing and evaluation of the deodorized product to ensure that the deodorization effect meets the requirements.

The use of deodorants in plastic products is an essential link. Everyone knows that if you use high-quality and odor-free plastic particles to make high-end plastic products, normally the plastic products are odor-free. But this means that you have to pay a high cost and it is difficult to win in the fierce market competition.

But adding plastic deodorants during the processing of plastic products is a different choice. You can use some recycled plastic pellets, which will be cheaper and more competitive in the market. Plastic deodorant solves the problem of odor in plastics, making your products more high-grade and higher premium. While you save costs, you can also pay a premium at the same time, and your profit margins are wider.