Odor remover can not only adsorb harmful substances formed in the plastic regeneration process, but also completely remove harmful substances through chelation. The microstructure of aluminum silicate, porous carrier, alumina and nano-silica, can not only increase the microscopic pores .At the same time, it increases the specific surface area of the deodorant without affecting the physical properties and mechanical strength of the recycled plastic.

PVC itself has no smell, but in order to produce products, it is necessary to add different additives and raw materials, such as heat stabilizers, optical brighteners, light stabilizers, plasticizers, lubricants, plasticization accelerators, etc. After adding these chemical additives, the product will have some residual chemical smell when exposed to high temperature. At this time, it is necessary to add some odor remover to remove the residual smell on the product. Thereby improving the environmental protection and health of the PVC product.

1.Performance and features:

Odor remover RT-10126 is a new deodorant developed for plastic products, widely used in PVC,PP,PE, especially for PVC transparent products, have good performance.

2. Physical Properties

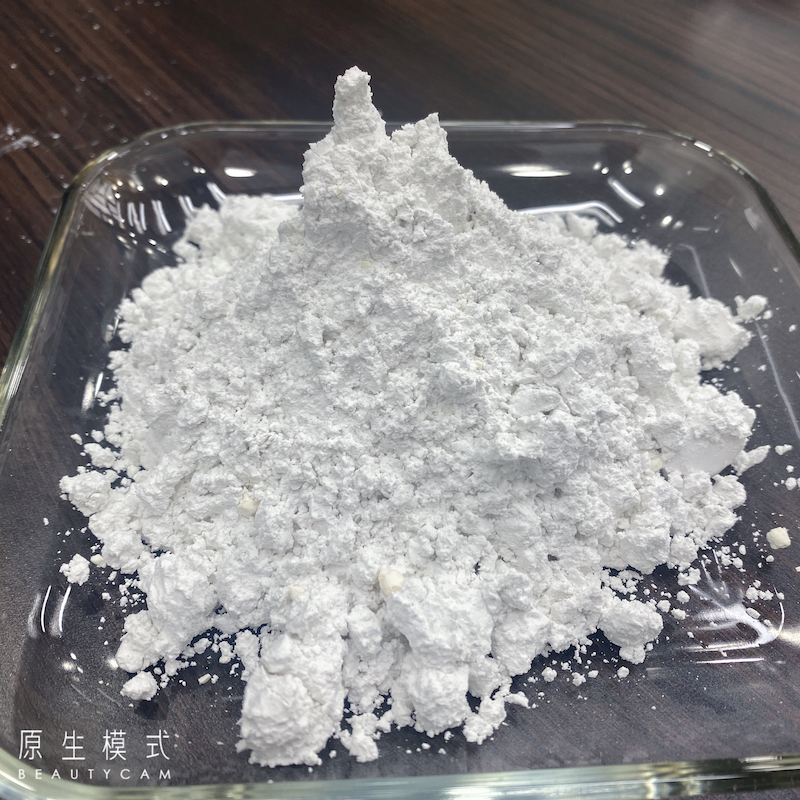

Appearance: White powder

Odor:Odorless

3.Method of Use:

The user mixes the Odor remover RT-10126 with the raw material as evenly as possible according to his own production conditions. The better the mixture, the better the deodorant effect.

Generally speaking, the higher the temperature, the more obvious the deodorization effect.(The temperature range is within 300 degrees).

For Masterbatch/Compound/Resin customers ,suggestion is that after the granulation, then bake in the oven at 80 degrees for 2-hours, and then comparing the result.

For End-users add the additives to produce products directly,it should place 24-hour , And then comparing the odor and VOC.

(All the above can be used as a reference. The specific operation can be formulated according to the customer's own processing technology.)

4.Dosage:

Applications: Polymer materials such as plastic PP PE PVC ABS.

Application Suggestion: Plastic PP PE PVC ABS: 0.1%-0.5%

Recycled material: 0.3%+ (increase the amount of reclaimed material according to the proportion of reclaimed material)

5.Packaging and storage:

Odor remover RT-10126 is powder form and 25KG are packed in one carton with aluminum packaging inside.

It should be stored in a clean, ventilated, dry place with storage period of 12 months.

6.Attention:

The odor remover is an alkaline substance, and it will turn yellow when it expose in the air, but it does not affect the performance.