The difference between Fluorescent brighteners OB and OB-1

Fluorescent brighteners OB and OB-1, these two products look the same as brothers, thought they are products of the same series, in fact, they are two completely different substances.

The differences of the physical parameters of the Fluorescent brighteners OB and OB-1 :

Fluorescent brighteners OB physical parameters:

Chemical name: 2,5-bis(5-tert-butyl-2-benzoxazolyl)thiophene

Molecular formula: C26H26N2O2S

Molecular weight: 430

Content: 99.5%

Ash content: 0.5%

Appearance: light yellow crystalline powder

Melting point: 201—203°C

Compatibility: soluble in organic solvents

Fluorescent brighteners OB-1 Physical parameters:

Chemical name: 4,4′-bis(2-benzoxazolyl) stilbene

Molecular formula: C28H18N2O2

Molecular weight: 414.45

Content: 99.5%

Ash content: 0.5%

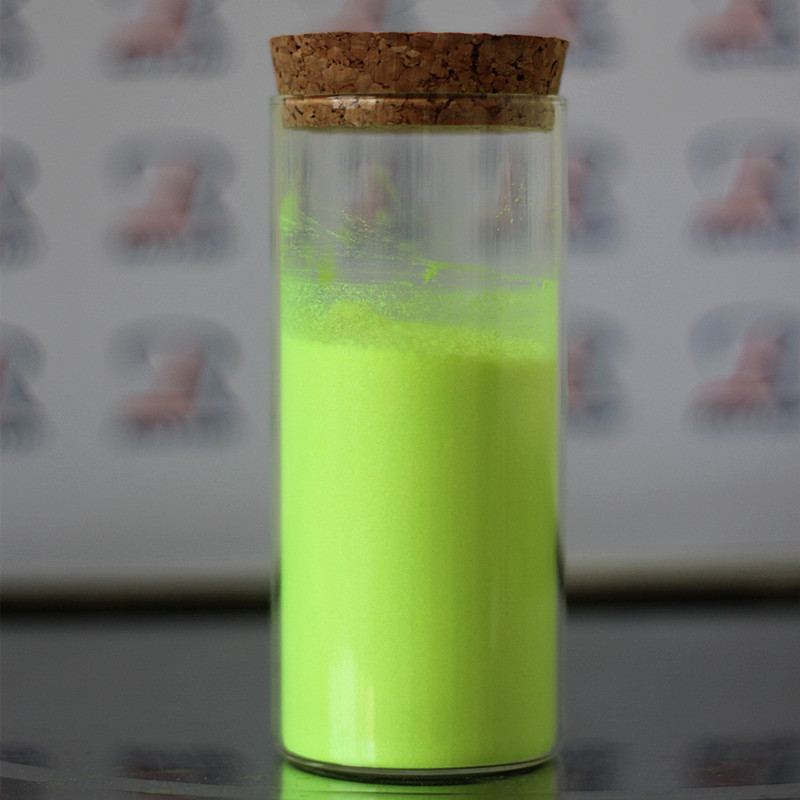

Appearance: yellow or yellow-green crystalline powder

Melting point: 355—360°C

Compatibility: soluble in organic solvents

The difference of molecular formula of Fluorescent brighteners OB &OB-1

The molecular formula of Fluorescent brighteners OB is C26H26N2O2S, and the molecular formula of OB-1 is C28H18N2O2. From the above picture, we can clearly see that the two are completely different chemical substances.

The difference between the uses of Fluorescent brighteners OB and OB-1.

Although they are two different chemical substances, from the naming, it can be guessed that there are many similarities between the two. For example, the fluorescent brighteners OB and OB-1 have a wide range of applications. Most of the plastics OB and OB-1 can be used universally, and the whitening and brightening effect is obvious. So, where is the difference?

1. The difference in melting point: OB-1>OB

Because the melting point of the optical brightener ob is 200 degrees, and the melting point of ob-1 is as high as 360 degrees, this determines that the optical brightener ob cannot be used for high-temperature plastic products, such as air conditioner casings and some kitchen utensils. Therefore, if your product requires high temperature processing, optical brightener ob-1 is your first choice.

2. The difference between dispersion and stability: OB>OB-1

Here, I must first explain that good dispersibility means that the product is easier to dissolve and evenly. For example, paint and ink have high requirements for the dispersibility of the fluorescent whitening agent; good stability means that the product is not easy to migrate and yellow in the later stage. For example, some inferior shoe soles were white and white when they were first bought, but they turned yellow and discolored after a short time. This shows that the stability of the fluorescent whitening agent is poor.

Of course, I am not saying that the dispersion and stability of the optical brightener ob-1 is not good, but it is slightly worse than ob. Because of this difference, we generally do not recommend the use of optical brightener ob-1 in ink coatings and soft plastics. Ob is relatively better in dispersibility and weather resistance, and yellowing migration is less likely to occur.

3. The price is the biggest difference between OB and OB-1

In fact, the biggest difference between the optical brightener OB and OB-1 is the price. When the fluorescent whitening agent first entered the market, their prices were similar, but due to the continuous increase in the production capacity of OB-1, the price also slowly dropped. Therefore, customers who can use the optical brightener OB-1 should choose OB-1 as much as possible. Those who have special requirements, such as high-end ink coatings and soft plastics, are recommended to use OB.