Article about PVC Wallpaper Production Process and Coating Formulation

Production Process:

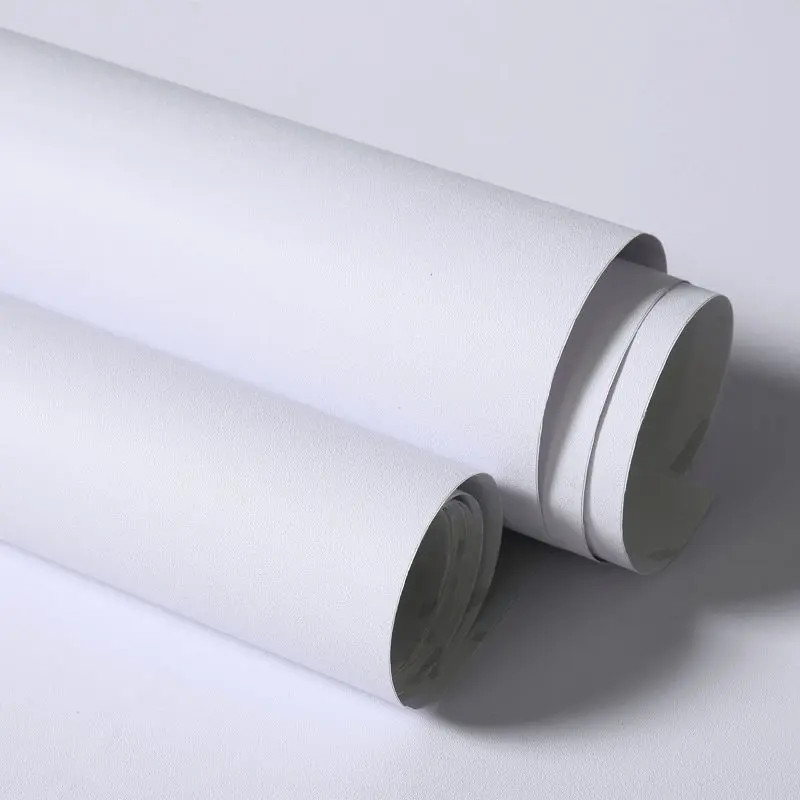

Sending the Base Paper: The production of PVC wallpaper begins with the transportation and preparation of the base paper, which serves as a stable foundation.

Coating: Coating is a crucial manufacturing step where the base paper is coated with a special mixture. The coating formulation includes PVC, DOP (plasticizer), calcium carbonate (used as a filler to increase hardness), an appropriate amount of stabilizers (to protect the balance of plasticization reaction and provide anti-oxidation properties to prevent yellowing), titanium dioxide (for covering), and a viscosity reducer (to address the tar-like odor generated during coating). The composition ratios of the coating vary based on the specific product requirements.

Drying (Gelation): The coated material undergoes a drying process, helping to solidify the coating and form the surface of the PVC wallpaper.

Cooling and Printing: Subsequently, the PVC wallpaper undergoes cooling and printing processes to achieve the desired patterns and colors.

Interlayer Drying: After printing, interlayer drying is performed to ensure that the patterns are firmly fixed onto the wallpaper.

Softening and Embossing: The wallpaper may require softening and embossing to attain specific textures and patterns.

Cooling: Cooling is essential to ensure the quality of PVC wallpaper and reduce potential deformation and shrinkage.

Trimming: The PVC wallpaper is trimmed to achieve the desired dimensions and shape.

Packing and Inspection: Quality inspection is conducted to ensure that the wallpaper meets the standards.

Rolling: PVC wallpaper is rolled up for ease of packaging and transportation.

Packaging and Boxing: Finally, the wallpaper is packaged and boxed, ready for delivery to customers.

Warehousing: The products are stored in a warehouse awaiting distribution.

Coating Formulation:

The coating formulation used during the coating process comprises the following main components:

PVC

DOP (plasticizer)

Calcium carbonate (filler, used to increase hardness)

Stabilizers (protecting the balance of the plasticization reaction and providing anti-oxidation properties)

Titanium dioxide (covering)

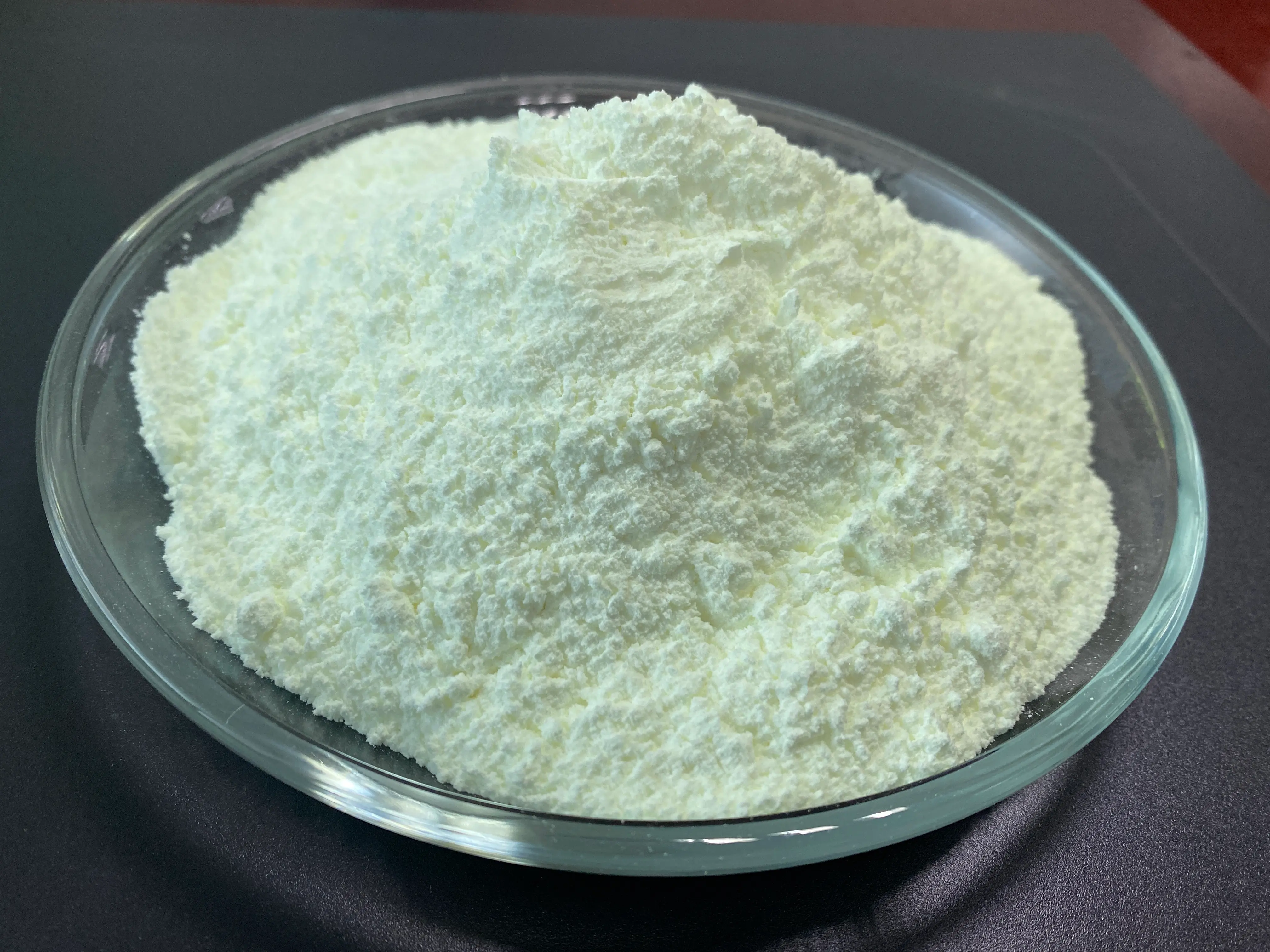

Optical brightener(reduce yellowish)

Viscosity reducer (addressing the tar-like odor generated during coating)

The specific composition ratios of the coating vary depending on the product type and requirements. For example, to produce foamed wallpaper, a foaming agent is added, while flame-retardant wallpaper requires the addition of flame retardants. Additionally, other components like brighteners and antioxidants may be added based on different product usage requirements.

It's worth noting that PVC wallpaper is sensitive to temperature and humidity during the coating process, making it susceptible to yellowing. Therefore, the selection of the appropriate optical brightening agent is crucial to ensure the final product's appearance and quality.

Enhancing Aesthetics with Optical Brightener for PVC Wallpaper

Optical brighteners have emerged as a game-changer in the world of PVC wallpaper production. These additives not only enhance the visual appeal but also extend the lifespan of wallpapers. In this article, we will explore the benefits of using optical brighteners, their application methods, and recommended usage for achieving stunning PVC wallpapers.

Optical Brightener: A Game-Changing Additive

Optical brighteners are fluorescent dyes that absorb UV light and re-emit it as visible blue light, thus brightening the appearance of materials they are applied to. In PVC wallpaper production, they play a pivotal role in achieving vibrant and long-lasting designs.

Advantages of Using Optical Brightener

Enhanced Visual Appeal:

Optical brighteners impart a brilliant and visually appealing glow to PVC wallpapers, making them stand out in any space.

Color Intensification:

They intensify the colors in the wallpaper, creating a more vivid and eye-catching display.

UV Protection:

Optical brighteners offer a level of UV protection, helping to preserve the colors and patterns of the wallpaper over time.

Improved Durability:

By reducing the effects of UV light and environmental factors, optical brighteners contribute to the longevity of PVC wallpapers.

Application Method:

Incorporation into PVC Formulation:

Optical brighteners are typically added during the formulation stage of PVC wallpaper production. They are mixed in with other components to ensure even distribution.

Proper Mixing:

It's crucial to ensure thorough and uniform mixing of the optical brightener within the PVC formulation. This guarantees consistent brightness across the entire wallpaper.

Recommended Usage:

The optimal dosage of optical brightener for PVC wallpaper depends on various factors including the specific type of brightener, the desired level of brightness, and the formulation of the PVC material. It is recommended to conduct trials to determine the ideal dosage for your particular application.

Dosage

The amount of optical brightener is often expressed as a percentage relative to the mass of the plastic. The amount of optical brightener used in plastics is related to its chemical structure, dispersion, and the properties of plasticizers or other additives in the plastic formulation. The dosage of optical brightener is generally 0.05%~0.1% (weight of plastic), and for ultra-white varieties, the dosage can reach 0.5% (weight of plastic) or more; for transparent plastics, the dosage is the above 1/100~1/10 of the dosage.

For example: the dosage of optical brightener OB-1 added per 100kg of polymer (reference dosage)

Transparent: Adding amount is 0.0025-0.005% (2.5g-5g)

The general dosage is: 0.0025-0.025% (2.5g-25g) not more than 0.03% (30g)

When adding any UV absorber to the polymer, attention should be paid to appropriately adjusting the optimal dosage of optical brightener OB-1.

Cautionary Notes:

Compatibility Testing:

Always conduct compatibility testing to ensure that the chosen optical brightener is compatible with the PVC formulation and does not adversely affect other additives or properties.

Regulatory Compliance:

Verify that the selected optical brightener complies with relevant industry standards and regulations for use in PVC wallpapers.

Optical brighteners have revolutionized the PVC wallpaper industry by enhancing visual appeal and extending product lifespan. Through careful formulation and dosage, manufacturers can achieve wallpapers that not only captivate with their vibrant colors but also endure over time. By leveraging the power of optical brighteners, PVC wallpapers continue to adorn spaces with lasting beauty and brilliance.

221.webp)