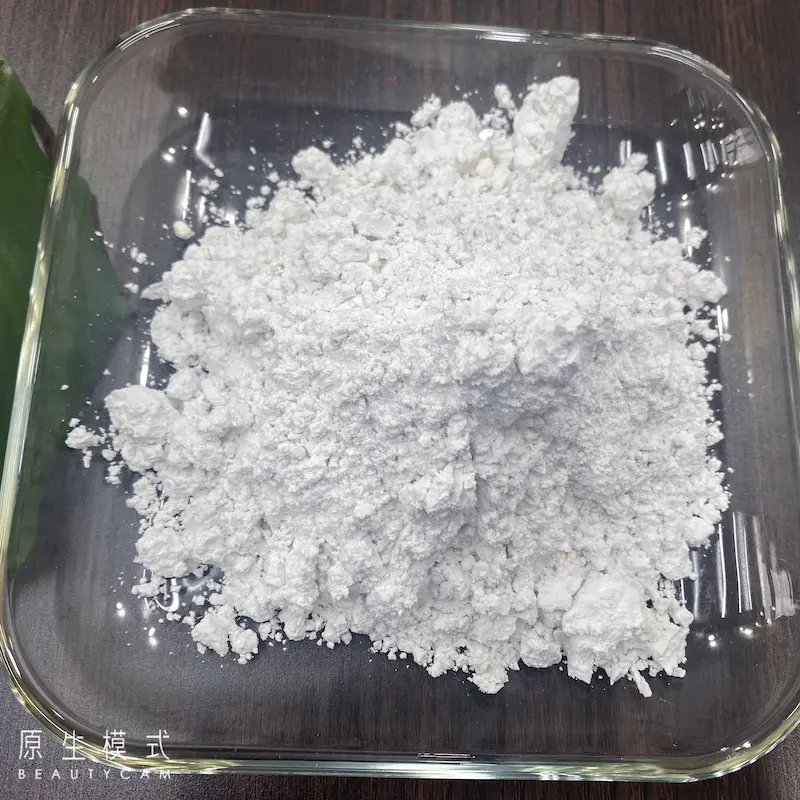

At present, masterbatch("color masterbatch")is widely used for plastic coloring. The color masterbatch is preliminarily mixed with optical brightener or pigment and the required resin plastic, and directly melted and extruded. The formed colorant products containing fluorescent brighteners or pigments with a relatively high concentration can be used directly, which has become a major means of plastic coloring.

When using color masterbatch, as long as the color masterbatch and resin are mixed uniformly in proportion, it can be directly used for the molding process of plastic products. A small amount of mixing only needs to be done by hand. In the case of a large amount of processing, in order to ensure the dispersion of the masterbatch, mechanical mixing can be used. After the masterbatch is mixed with the resin plastic machine, it can be sent to an injection molding machine with a pre-plastic device for coloring while pre-molding.

Generally speaking, the mixing ratio of color masterbatch and resin is relatively wide, ranging from 1:10 to 1:100. This mainly depends on the content of the fluorescent brightener in the color masterbatch and the fluidity of the plastic. According to the experience of plastic engineering and technical personnel, the mixing fluidity sequence of common plastics is as follows:

GPS→PE (high melt index)→PE (low melt index), PP (low melt index), PVC→HIPS→ABS, SAN→PC, PA, NY.

According to the above sequence, the same injection molding equipment can be used as a reference for the process in terms of operation and ratio selection. For plastics with good mixing properties, the mixing ratio can be smaller, and the mixing ratio of color masterbatches with poor mixing properties can be appropriately enlarged, and attention should be paid to the process.

The control of the screw of the injection molding machine is the key to uniform dispersion of the color masterbatch. The screw is generally divided into three sections: feeding section, compression section, and metering section. In order to make the color masterbatch melt as soon as possible after entering the barrel, so as to be uniformly mixed with the plastic, when using the color masterbatch, the temperature of the feeding section should be appropriately increased to make it close to the temperature of the compression section or slightly higher. If the temperature in the feeding section is too low, the color masterbatch will only melt in the compression section, and the pre-plasticization time will be relatively shortened. This will easily cause uneven product coloring and streaks. Pay more attention to engineering plastics with low fluidity and difficult to mix.

In the process of using color masterbatch injection, pay attention to applying a certain back pressure, which can improve the mixing effect of the screw and make the color masterbatch spread more evenly. The amount of back pressure applied depends on the actual effect of different equipment.

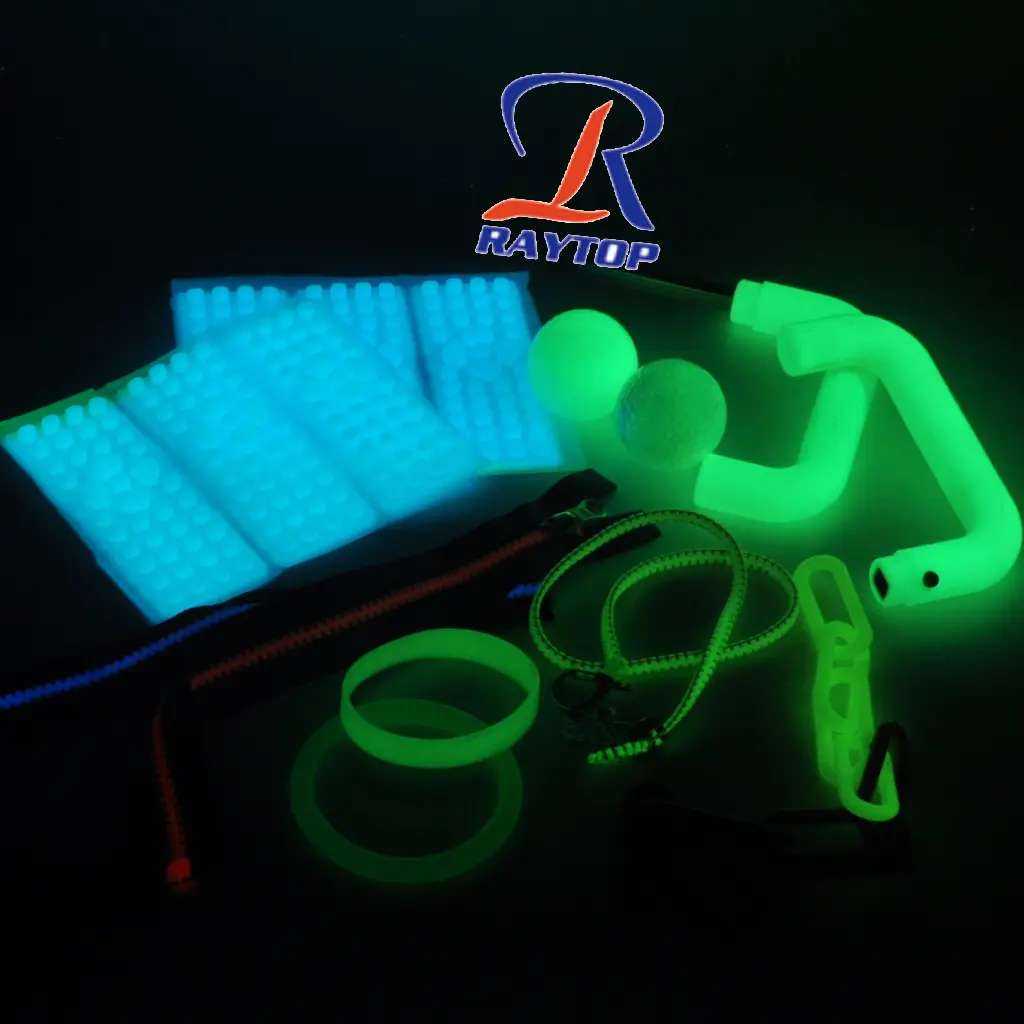

Because the amount of Optical Brightener is very small, the masterbatch used only needs to be accurately measured, and a certain amount of it is mixed into the material before plastic molding to achieve the purpose of coloring and whitening, which is quite convenient. It also reduces dust, greatly improves the working environment, and is loved by many manufacturers. At present, fluorescent whitening agent masterbatch products are available to the market. Plastics colored in this way include polyvinyl chloride, polyethylene, polypropylene and so on. Generally, injection molding, extrusion pipes, extruded films, wire coatings, hollow molded products or sheets with mixing equipment are suitable for coloring with masterbatch.

221.webp)